A flag stands for a set of principles; the reach for the ideals of a civilization–

not for the lapses of adherence to them.

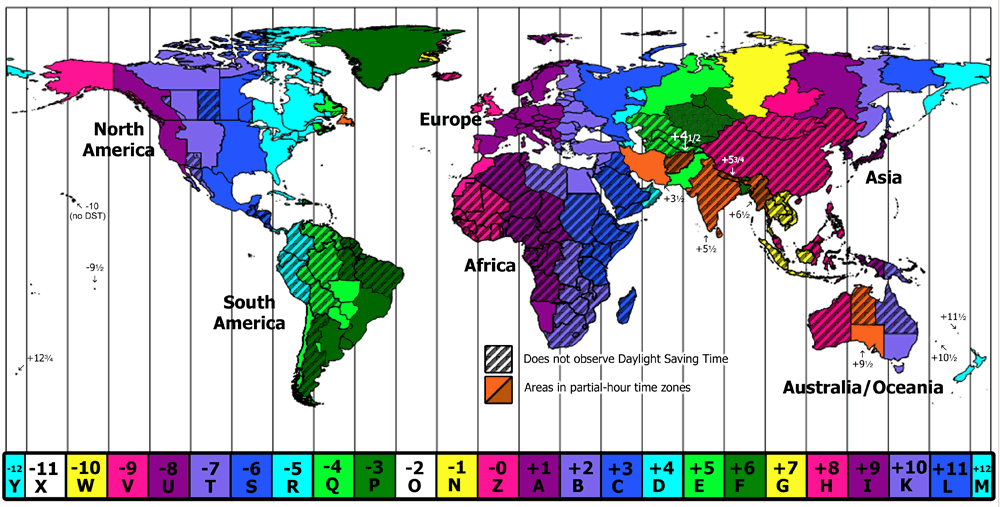

Flag Day in the United States, observed on June 14th, commemorates the adoption of the American flag by the Second Continental Congress in 1777. It’s a day to honor the symbol of the nation’s unity, freedom, and democracy. The flag represents the ideals and principles upon which the country was founded, including liberty, justice, and equality.

On Flag Day, Americans typically display the flag at their homes and businesses, participate in patriotic ceremonies, and reflect on the significance of the flag in American history and culture. It’s also a time to remember the sacrifices made by those who have served and continue to serve in defense of the nation. Flag Day serves as a reminder of the values that bind Americans together as one nation, under the banner of the stars and stripes.

There are no rigorous standard heights for flagpoles displaying the American flag in educational settlements but there are general guidelines and recommendations.

Commercial Use: In commercial settings, flagpoles can vary widely depending on the size of the building and the surrounding landscape. They can range from 20 feet for smaller businesses to over 100 feet for large corporate buildings.

Government Buildings: Flagpoles at government buildings or public spaces often range from 30 to 60 feet or more, depending on the size and prominence of the building.

Proportions: A general guideline for the American flag is that the length of the flag should be about one-quarter to one-third the height of the flagpole.

Regulations: Some local ordinances or homeowner associations may have specific guidelines regarding flagpole height, so it’s a good idea to check local regulations before installing one.

Ultimately, the height of a flagpole for the American flag depends on the context and purpose of display, as well as practical considerations such as the size of the flag itself and local regulations.

It’s a perfect day for school in @DGDistrict58! Such a fun morning visiting with the Lester students, staff, and families. It’s great to be in 58! #dg58pride pic.twitter.com/bwHlROpbMw

— Dr. Kevin B. Russell (@drkevinbrussell) August 30, 2023

NB: “The flag stands for a set of principles, not the lack of adherence to them.” ― Craig D. Lounsbrough. We are not sure about this source; nor the author. We have adapted the sentiment for our home page excerpt.