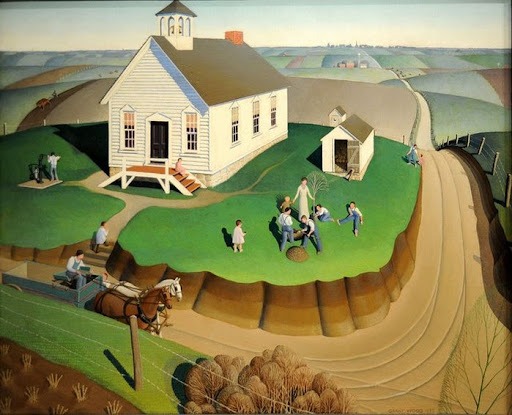

“Buildings, too, are children of Earth and Sun.”

— Frank Lloyd Wright:

Today we sort through the best practice literature for designing and building education settlements with brick — the world’s oldest construction material. Masonry is a term used to describe the construction of structures using individual units that are bound together with mortar. Brickwork is a specific type of masonry that involves the use of bricks as the primary building units.

We use the terms interchangeably reflecting vernacular use in the literature. Brickwork in building construction lies in its ability to provide structural strength, fire resistance, thermal and sound insulation, aesthetic appeal, low maintenance, environmental friendliness, cost-effectiveness, and versatility.

Use the login credentials at the upper right of our homepage.

The genius of bricklayers on view here. A wonderfully ornamental effect is achieved almost entirely through ingeniously combining 228*108*54mm cuboids of baked mud. No sculpted mouldings, no fine imported materials, just brilliant and thoughtful craftmanship. pic.twitter.com/KxZw2HmFLD

— Samuel Hughes (@SCP_Hughes) October 19, 2023

Masonry is a construction technique that involves the use of individual units, typically made of materials like brick, stone, concrete blocks, or clay tiles, which are bound together with mortar to create walls, columns, or other structural elements. Masonry has been used for thousands of years and remains a popular method for building various structures, including houses, commercial buildings, bridges, and more.

The key components of masonry construction are:

- Masonry Units: These are the individual building blocks or pieces, such as bricks or stones, that form the structure. They come in various shapes, sizes, and materials, depending on the specific requirements of the project.

- Mortar: Mortar is a mixture of cement, sand, and water that is used to bind the masonry units together. It acts as both an adhesive and a filler between the units, providing strength and stability to the structure.

- Masonry Workmanship: Skilled craftsmen, known as masons, are responsible for arranging and securing the masonry units with mortar. Their expertise ensures the structural integrity and aesthetic quality of the finished product.

Masonry construction offers several advantages:

- Durability: Masonry structures are known for their longevity and resistance to fire, weather, and pests.

- Aesthetic Appeal: Masonry can be used to create intricate designs and patterns, making it a popular choice for architectural and decorative elements.

- Energy Efficiency: Masonry walls have good thermal mass, which can help regulate indoor temperatures and reduce energy costs.

- Low Maintenance: Masonry structures typically require minimal maintenance over the years.

Masonry can be categorized into different types based on the materials and methods used. Some common forms of masonry include:

- Brick Masonry: This involves using clay or concrete bricks to build walls and structures. It is widely used in residential and commercial construction.

- Stone Masonry: Natural stones, such as granite, limestone, and slate, are used to create walls and structures in this type of masonry. It’s often used for historical or architectural projects.

- Concrete Block Masonry: Concrete blocks are used to construct walls in this form of masonry, and it’s commonly seen in industrial and commercial buildings.

- Reinforced Masonry: Steel reinforcement is incorporated into masonry walls to enhance structural strength.

Masonry is a versatile construction method that can be used in various applications, and it continues to be a fundamental part of the construction industry.

More:

College of West Anglia: Bricklayer Apprenticeship

North Carolina State University Industry Expansion Solutions: Fireplace & Chimney Safety

Salt Lake Community College: Brick Mason

Occupational Safety and Health Administration: Fall Protection