Nearly 1 Billion YouTube views. Astronomical.

After moonlighting in several underground Detroit bands as a drummer, Jack White founded the White Stripes with fellow Detroit native and then-wife Meg White in 1997. He graduated from Cass Tech High School and attended Wayne State University as a dramatic arts student; thereafter receiving an honorary degree; and since awarded eight Grammy Awards, among them, for his work on the soundtrack of “Cold Mountain”.

Detroit’s Wayne State University introduces world to Dr. Jack White

Rolling Stone: Jack White Saves Detroit Masonic Temple from Foreclosure

“Seven Nation Army” is one of the most iconic and popular songs of the early 21st century and is routinely performed at athletic events at all levels in the United States. Its view count on YouTube is closing in on 1 billion. Several factors contributed to the song’s popularity:

Memorable Guitar Riff: The song is instantly recognizable for its distinctive and powerful guitar riff played by Jack White. The riff, created using a semi-acoustic guitar and an octave pedal, became an anthem for many music enthusiasts.

Catchy Chorus: The song features a catchy and memorable chorus with the repeated lyrics, “I’m gonna fight ’em off, a seven nation army couldn’t hold me back.” This repetition and simplicity added to its appeal and made it easy for listeners to sing along.

Sports and Pop Culture: “Seven Nation Army” transcended the music scene and found its way into various aspects of popular culture. The song became a favorite at sports events around the world, particularly in stadiums and arenas. Its use in sports contexts, such as football chants, contributed to its widespread recognition.

Critical Acclaim: The song received critical acclaim for its raw energy, innovative sound, and Jack White’s distinctive vocals. It won a Grammy Award for Best Rock Song in 2004 and became a defining track for The White Stripes.

Cover Versions and Remixes: The song’s popularity was further fueled by numerous cover versions and remixes by various artists across different genres. This contributed to its longevity and continued relevance in diverse musical contexts.

As a result of these factors, “Seven Nation Army” has endured as a cultural phenomenon, maintaining its popularity long after its initial release.

I’m gonna fight ’em off

A seven nation army couldn’t hold me back

They’re gonna rip it off

Taking their time right behind my back

And I’m talking to myself at night

Because I can’t forget

Back and forth through my mind

Behind a cigarette

And the message coming from my eyes

Says “Leave it alone”

Don’t want to hear about it

Every single one’s got a story to tell

Everyone knows about it

From the Queen of England to the Hounds of Hell

And if I catch it coming back my way

I’m gonna serve it to you

And that ain’t what you want to hear

But that’s what I’ll do

And the feeling coming from my bones

Says “Find a home”

I’m going to Wichita

Far from this opera forevermore

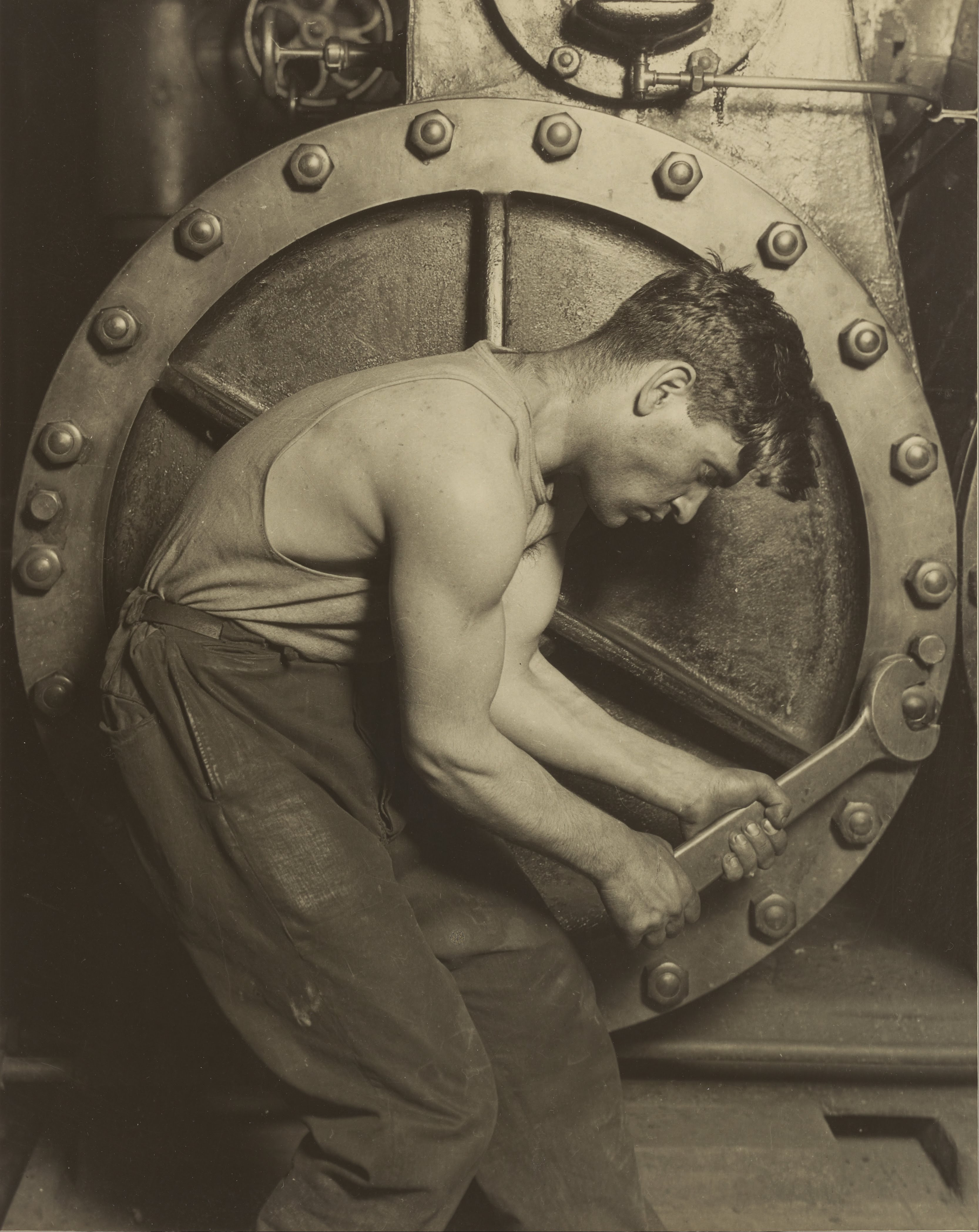

I’m gonna work the straw

Make the sweat drip out of every pore

And I’m bleeding, and I’m bleeding, and I’m bleeding

Right before the Lord

All the words are gonna bleed from me

And I will sing no more

And the stains coming from my blood

Tell me “Go back home”