Tag Archives: North Carolina

- Home

- Posts tagged "North Carolina" (Page 2)

LIVE: $180 Million Integrated Life Science Building

Integrative Sciences Initiative: Fostering Cross-Discipline Collaboration at NC State

North Carolina State University Facilities Services

Notification of Open-Ended Contracts 2023-2024

A little spring in our step. 🌸✨ #NCStateOnCampus pic.twitter.com/s5s01TYfOX

— NC State University (@NCState) March 5, 2024

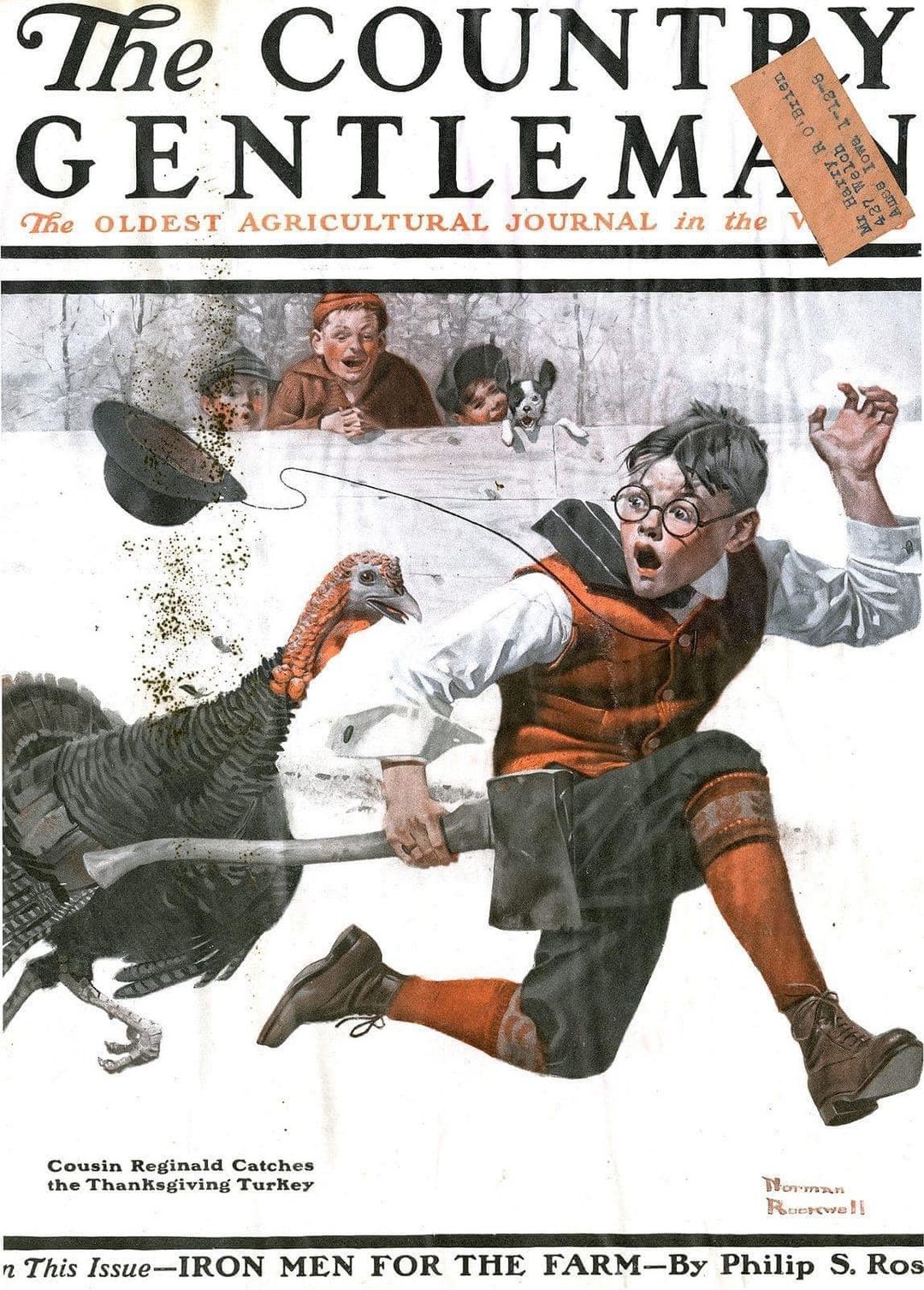

Commemorative Coffee

Picture of the exterior of the Old Main Administration Building with students outside on the grounds before the fire. Click image for a view of the building after the fire.

Elon University Facilities Management

The Great Seattle Fire (1889) – University of Washington:

The University of Washington’s original campus was affected by the Great Seattle Fire in 1889. While not exclusively a college campus fire, it had a significant impact on the university.

University of Michigan Economics Building (1980):

Built in 1856. First chemical laboratory at a state university. Building served medical students and others as both laboratory and classroom. Situated just west and south of the original medical building. Additions made to the one-story building in 1861, 1866, 1868, 1874. In 1880 a two-story addition was added. In 1890, a three-story wing was added to the west of the original structure and was designed by E. W. Arnold of Detroit. A final addition was constructed in 1901. With the completion of the West Medical Building (later renamed the Dana Building) in 1903 and the Chemistry Building in 1909, the laboratories were transferred from the original Chemical Laboratory. In 1908, it became the Economics Building with Pharmacology occupying the north wing. Destroyed by an arson fire Christmas Eve 1981.

Seton Hall University Dormitory Fire (2000) – New Jersey:

A fire in a dormitory at Seton Hall University in 2000 resulted in three fatalities and numerous injuries. The incident led to increased awareness of fire safety in college campuses.

Harvard University Laboratory Fire (2006) – Massachusetts:

A chemical explosion and fire occurred at a Harvard University laboratory in 2006, resulting in injuries to several people. This incident highlighted the importance of safety measures in research facilities.

University of Missouri-Columbia Residence Hall Fire (2011) – Missouri:

A fire broke out in a residence hall at the University of Missouri-Columbia in 2011, leading to the evacuation of students. Fortunately, there were no reported injuries.

University of Delaware Chemistry Lab Fire (2013) – Delaware:

A laboratory fire occurred at the University of Delaware in 2013, prompting the evacuation of a chemistry building. No injuries were reported, but it emphasized the need for safety protocols in academic laboratories.

Paper Cleaner

Centrifugal paper cleaners are used in the pulp and paper industry to remove unwanted contaminants from pulp or paper stock. These contaminants can include dirt, sand, shives, small fibers, and other impurities that can affect the quality of the final paper product. Centrifugal cleaners work on the principle of centrifugal force and are typically installed in the stock preparation stage of papermaking processes. Here’s how they work:

Inlet: The pulp or paper stock containing contaminants is fed into the centrifugal cleaner through an inlet. The inlet is designed to create a tangential flow of the stock, which imparts a swirling motion to the mixture.

Centrifugal Force: Once inside the cleaner, the stock and contaminants are subjected to centrifugal force due to the rapid rotation of the cleaner’s inner drum or rotor. The centrifugal force causes the heavier contaminants to move toward the outer wall of the cleaner, while the cleaner stock moves toward the center of the drum.

Separation: The contaminants, being heavier, are forced against the outer wall of the cleaner by the centrifugal force, and they accumulate there. The clean stock, which is lighter and free of contaminants, moves toward the center of the cleaner.

Outlet: The cleaned stock exits the cleaner through the center outlet, while the accumulated contaminants are removed from the outer wall. The contaminants can be periodically purged from the cleaner to maintain its efficiency.

Adjustment: Centrifugal cleaners often have adjustable settings to control the separation efficiency. Operators can vary the cleaner’s operating parameters, such as the feed rate, drum speed, and cone angle, to optimize the separation process for different types of contaminants and pulp or paper stocks.

They can operate continuously and provide high efficiency in removing heavy contaminants such as coffee filters. They are often used in conjunction with other cleaning processes, such as screening and flotation, to achieve the desired quality and cleanliness of the pulp or paper stock before it is used in the papermaking process.

Facilities: North Carolina State University

Appian Way

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Embedded Systems

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

WKNC-FM 88.1

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670