In any industry painting (and decorating) operations play a crucial role in facility management by enhancing the overall appearance, protecting surfaces, and maintaining a healthy and conducive environment. In the education industry we find these operations in both the business and academic units; often co-mingled with sign-making shops.

- Aesthetics and Branding: Fresh coats of paint revitalize the appearance of walls, ceilings, doors, and other surfaces, creating a clean and inviting environment. Painting can also be used strategically to incorporate branding elements, such as company colors or logos, to reinforce brand identity throughout campus. Bright, vibrant colors can stimulate creativity and engagement, while well-chosen color schemes can create a sense of calm and focus.

- Surface Protection: Color coatings are a protective barrier for surfaces, shielding them from environmental factors like moisture, sunlight, dust, and regular wear and tear. It helps prevent structural damage, corrosion, and deterioration, extending the lifespan of various components in the facility, including walls, floors, metal structures, and equipment.

- Maintenance and Preservation: Regular painting operations are part of preventive maintenance programs in facility management. By addressing minor issues like peeling, cracks, or stains on surfaces, painting helps maintain a well-maintained and professional appearance. It prevents further damage and the need for costlier repairs in the future. Using environmentally conscious paints contributes to sustainable practices and healthier indoor air quality.

- Functional Differentiation: Painted color variations are utilized to differentiate various spaces within a facility. By using different colors, patterns, or textures, specific areas can be designated for different purposes, such as work zones, storage areas, or recreational spaces. This assists with wayfinding and enhances overall functionality.

Today at 15:00 UTC we review best practice literature for large-scale painting operations — an exploration different than the one undertaken during our Fine Art and Signs, Signs, Signs colloquia — with attention to worker and chemical safety. Among these considerations:

- Falls from Heights: When painting large structures such as buildings or bridges, workers often need to work at elevated heights using ladders, scaffolding, or aerial lifts. Falls from heights are a significant hazard, and proper fall protection systems, such as guardrails, harnesses, and safety nets, should be in place to prevent accidents. Large-scale painting operations may require workers to access or work on structures that have structural weaknesses, corroded surfaces, or unstable platforms.

- Inhalation of Hazardous Substances: Paints, coatings, solvents, and other chemicals used in large-scale painting operations can release volatile organic compounds (VOCs) and other harmful substances. Prolonged exposure to these chemicals, particularly in poorly ventilated areas, can lead to respiratory problems, dizziness, skin irritation, or other health issues. Proper personal protective equipment (PPE) like respirators, gloves, and protective clothing should be provided and used to minimize exposure risks.

- Skin and Eye Irritation: Contact with paint, solvents, or other chemicals can cause skin irritation, dermatitis, or allergic reactions. Splashes or spills can also result in eye injuries. Workers should wear appropriate protective clothing, such as gloves, coveralls, and safety goggles, to protect their skin and eyes from direct contact with hazardous substances.

- Fire and Explosion Risks: Some paints and solvents are flammable or combustible, posing fire and explosion risks, especially in enclosed spaces or areas with inadequate ventilation. Strict adherence to fire safety measures, including proper storage and handling of flammable materials, use of spark-proof tools, and implementing effective fire prevention protocols, is crucial.

- Weather Conditions: Outdoor large-scale painting operations are often subject to weather conditions, such as extreme temperatures, high winds, or rain. Adverse weather conditions can pose risks to workers’ safety and affect the quality of paint application. Adequate weather monitoring and planning, along with appropriate safety measures and protective equipment, are necessary to mitigate these hazards.

Open to everyone. Use the login credentials at the upper right of our home page.

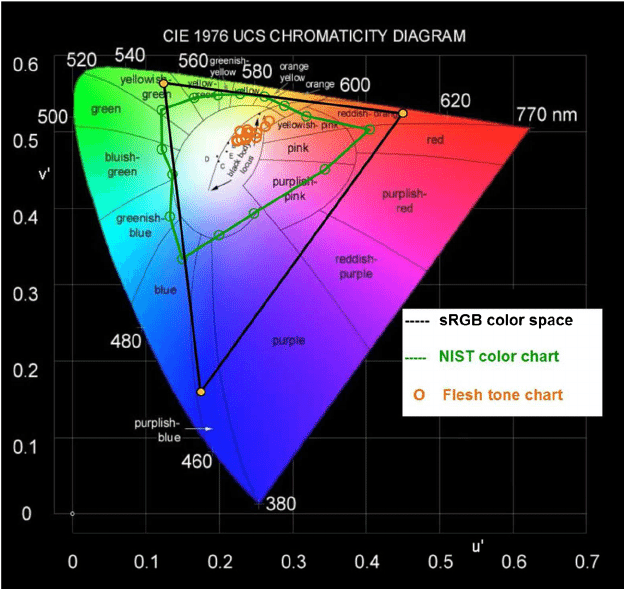

ASTM’s color and appearance committee (E12) has approved a new standard that will be useful in calculating the colors of objects. The new standard (E3415) expands on color calculations described in ASTM’s standard on CIE colorimetric systems (E308). https://t.co/7F97dcFkVe pic.twitter.com/zcAp6DT1tg

— ASTM International (@ASTMIntl) October 15, 2024

Relevant standards:

Chemistry

ASTM D-series titles

EN 1504-2: Products and systems that are graffiti-resistant

ISO 12944: Paints and varnishes

Application and Fire Safety

Institute of Electrical and Electronic Engineers: Self-Operating Paint Bot

National Fire Protection Association

Occupational Safety and Health Administration

logical pic.twitter.com/V0UoqMMXdB

— Enez Özen (@Enezator) August 24, 2024

ASTM’s color and appearance committee (E12) has approved a new standard that will be useful in calculating the colors of objects. The new standard (E3415) expands on color calculations described in ASTM’s standard on CIE colorimetric systems (E308). https://t.co/7F97dcFkVe pic.twitter.com/5GCfEgP4TI

— ASTM International (@ASTMIntl) September 30, 2024