We find town-gown political functionaries working to accommodate students traveling on micro-scooters. Several non-profit trade associations compete for “ownership” of some part of the economic activity associated with micromobility. One of several domain incumbents is SAE International. Here is how SAE International describes the micromobility transformation:

“…Emerging and innovative personal mobility devices, sometimes referred to as micromobility, are proliferating in cities around the world. These technologies have the potential to expand mobility options for a variety of people. Some of these technologies fall outside traditional definitions, standards, and regulations. This committee will initially focus on low-speed micromobility devices and the technology and systems that support them that are not normally subject to the United States Federal Motor Vehicle Safety Standards or similar regulations. These may be device-propelled or have propulsion assistance. They are low-speed devices that have a maximum device-propelled speed of 30 mph. They are personal transportation vehicles designed to transport three or fewer people. They are consumer products but may be owned by shared- or rental-fleet operators. This committee is concerned with the eventual utilization and operational characteristics of these devices, and how they may be safely incorporated in the transportation infrastructure. This committee will develop and maintain SAE Standards, Recommended Practices, and Information Reports within this classification of mobility. The first task of the committee will be to develop a taxonomy of low-speed micromobility devices and technologies. Currently, many of these terms are not consistently named, defined, or used in literature and practice. This task will also help refine the scope of the committee and highlight future work….”

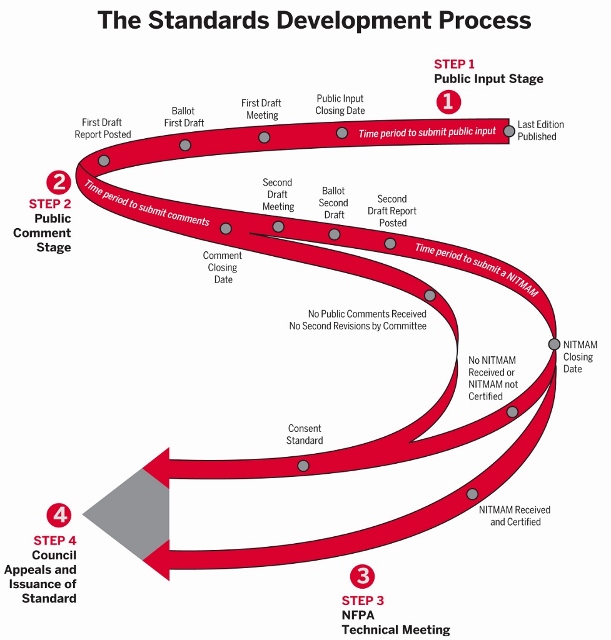

Micromobility standards development requires sensitivity to political developments in nearly every dimension we can imagine.

Specifically, we follow developments in SAE J3194: Taxonomy and Definitions for Terms Related to Micromobility Devices. Getting scope, title, purpose and definitions established is usually the first step in the process of developing a new technical consensus product. From the project prospectus:

This Recommended Practice provides a taxonomy and definitions for terms related to micromobility devices. The technical report covers low-speed micromobility devices (with a maximum device-propelled speed of 30 mph) and the technology and systems that support them that are not normally subject to the United States Federal Motor Vehicle Safety Standards or similar regulations. These devices may be device-propelled or have propulsion assistance. Micromobility devices are personal transportation vehicles designed to transport three or fewer people. They are consumer products but may be owned by shared- or rental-fleet operators. This Recommended Practice does not provide specifications or otherwise impose requirements of micromobility devices.

SAE standards action appears on the pages linked below:

SAE Standards Development Home Page

SAE International is proud to announce the release of SAE J3400™ North American Charging Standard (NACS) Electric Vehicle Coupler Technical Information Report.

Click the link for more information: https://t.co/diauiuev97 pic.twitter.com/zjK5sf1R6L

— SAE International® (@SAEIntl) December 19, 2023

Apart from the rising level of discussion on vehicle-to-grid technologies (which we track more closely with the IEEE Education & Healthcare Facilities Committee) there is no product at the moment that business units in the education industry can comment upon. Many relevant SAE titles remain “Works in Progress”. When a public commenting opportunity on a candidate standard presents itself we will post it here.

We host periodic Mobility colloquia; SAE titles standing items on the agenda. See our CALENDAR for the next online session; open to everyone.

Issue: [19-130]

Category: Electrical, Facility Asset Management, Transportation

Colleagues: Mike Anthony, Paul Green, Jack Janveja, Richard Robben

LEARN MORE:

Inspiring a College Campus to Design, Create, and Build Green Small Engine Vehicles 2009-32-0107