Tag Archives: michc

- Home

- Posts tagged "michc"

Well Water

Michigan Central | Water 330 | 2021 Michigan Plumbing Code

Protect the water quality of your water well

One of the first activities upon waking is interacting with water. Approximately 25% of households in the state of Michigan rely on private well water as their primary drinking water source. This figure comes from the Michigan Department of Environment, Great Lakes, and Energy (EGLE), which estimates nearly 1.12 million households use private wells out of a total of roughly 4.1–4.6 million households statewide (based on U.S. Census data and population estimates of about 10 million residents, with an average household size of 2.5).

Other sources, such as Michigan State University Extension and the Michigan Water Stewardship Program, report slightly higher figures of 44–45% for overall groundwater reliance (including public systems drawing from aquifers), but the specific share for private household wells aligns with the 25% estimate from EGLE. Rural and southeastern areas of the state have the highest concentrations.

Sunday Brunch Menu | 10:30 – 1:30 AM Heritage Room

Michigan State was recently named a “dream school” in the nation, a university that’s not focused on prestige, but on value, access and outcomes. pic.twitter.com/ZMnO5szPMd

— MSU (@michiganstateu) November 7, 2025

Most non-Midwesterners have no idea how violent and deadly the Great Lakes get 🙏🙏 pic.twitter.com/25coVuUjaM

— G-PA INDY (@GPAIndiana) November 8, 2025

Hot chocolate vs. hot cocoa

2026 General Fund Revenue & Expenditures: $1.738B $ Integrated Facilities and Land Use

MSU receives record-breaking $401 million commitment

Why Does The Modern World Make No Sense?

“…Hot cocoa and hot chocolate are terms that we often used interchangeably. Technically, hot cocoa and hot chocolate are as different as milk chocolate and bittersweet chocolate. Hot cocoa is made with cocoa powder, the way my mother made it when I was a kid. Hot chocolate is made from melting chocolate bars into cream…”

Plant science at your dinner table: Hot chocolate vs. hot cocoa

Black coffee at restaurants should not be $5. I’m not drinking the whole pot. I just want a cup. pic.twitter.com/wxy5xO4srV

— Blonde Musings 🇺🇸 Courtney (@musings_blonde) February 1, 2026

You’ve never heard the fight song like this.

MSU College of Music students, faculty and alumni picked up classroom instruments and turned them into something unforgettable.

No sheet music. No rehearsal. Just serious music skills and some Spartans Will. pic.twitter.com/a1yPaLXLDQ

— MSU (@michiganstateu) July 31, 2025

The clarity of this first hour—the pensive hope of winter—the ritual morning brings. These are the things. pic.twitter.com/CwdExLn5gC

— 1000yearhouse (@1000yearhouse) January 27, 2026

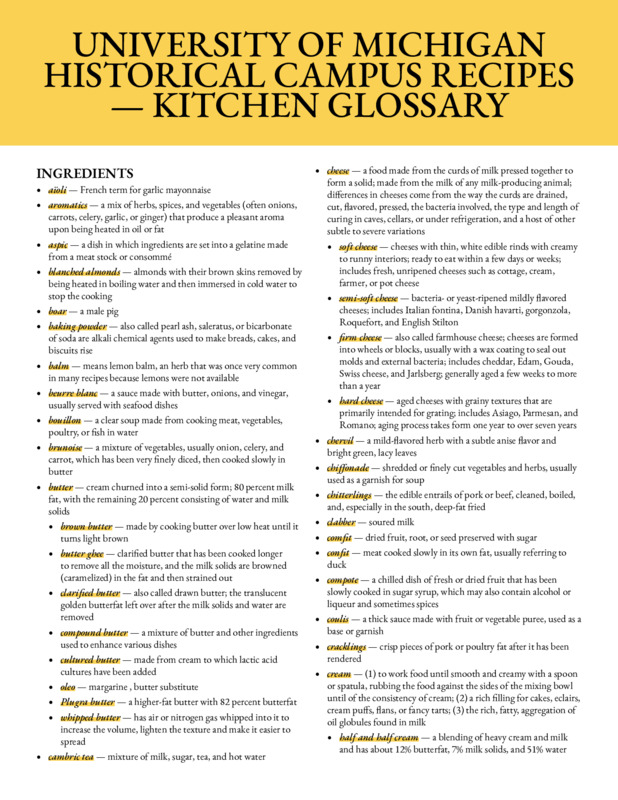

Integrated Planning Glossary

Connections, learnings, and expanded conversations #SCUPNC2022 in #chicago 👍🌟 pic.twitter.com/enPtA7YJsX

— SCUP (@Plan4HigherEd) October 18, 2022

Early operations benefited from administrative support (aegis) provided by the University of Michigan, including office space and resources in Ann Arbor. This arrangement persisted until a financial crisis in the late 1970s (1976–1980), during which SCUP relocated to New York.

The decoupling—marking full operational and administrative independence from the University of Michigan—occurred in 1980, when SCUP returned to Ann Arbor as a self-sustaining nonprofit headquartered at a separate location –1330 Eisenhower Place — less than a mile walk from Standards Michigan‘s front door at 455 East Eisenhower.

* Of the 220 ANSI Accredited Standards Developers, the State of Michigan ranks 3rd in the ranking of U.S. states with the most ANSI-accredited standards developers (ASDs) headquartered there; behind the Regulatory Hegemons of California and ChicagoLand and excluding the expected cluster foxtrot of non-profits domiciled in the Washington-New York Deep State Megalopolis. Much of Michigan’s presence in the private consensus standards space originates from its industrial ascendency through most of the 1900’s.

Cheesy Hamburger Skillet

C

MSU’s Extension’s Beef Production program supports Michigan’s beef industry through research, education, and outreach to enhance producer profitability, sustainability, and quality of life. It focuses on key areas like nutrition, genetics, grazing management, health, reproduction, and economics. Notable efforts include advancing grass-fed beef systems, feedlot management, and beef x dairy crossbreeding.

Conducted at facilities such as the Lake City and Upper Peninsula Research Farms, the program offers workshops, resources (e.g., pricing tools, disease prevention guides), and youth education via 4-H market beef projects and family recipes.

Our Master Gardeners are wrapping up a great educational tour of Alberta and British Columbia, Canada. They participated in learning opportunities at Canadian National Parks, agricultural sites, and gardens, and gained a better understanding of Indigenous and Asian cultures. pic.twitter.com/47jcrlYJfv

— MSU Extension (@MSUExtension) July 30, 2024

Steve and Amy Van Andel Graduate School of Government

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

The Common Cup

Michigan Central Summer Fall | Michigan Central Winter Spring

Open every day since 2007: offering locally sourced coffee, teas, baked goods, and a welcoming space for studying or events. Across Linden Street from First Presbyterian Church of Ann Arbor, Angell Elementary School and footsteps away from Chi Omega and seven other sororities and fraternity houses on the oddly-shaped lot bounded by South University. Washtenaw and Hill Streets.

A post shared by The Common Cup (@thecommoncupcoffee)

The University Lutheran Chapel in Ann Arbor, Michigan was designed by architect Glen Paulsen in 1959; a local Ann Arbor architect known for his modernist work and close ties to the University of Michigan community. The chapel is one of his most celebrated designs and is widely regarded as an outstanding example of mid-20th-century ecclesiastical architecture in the Midwest. The dramatic hyperbolic-paraboloid roof and the integration of natural light through colored glass strips are signature elements of the building.His work often emphasized clean lines, structural expression (e.g., exposed concrete and steel), and integration with natural surroundings, influenced by his time with Eero Saarinen and his teaching roles at the University of Michigan and Cranbrook Academy of Art. While the University Lutheran Chapel (1959) in Ann Arbor exemplifies his ecclesiastical modernism with its hyperbolic-paraboloid roof, below is a curated list of his other key projects, drawn from biographical records, architectural archives, and historical surveys. In the fullness of time his private practice from 1958 to 1969 morphed into TMP (Tarapata-MacMahon-Paulsen, 1969–1977).

Eggnog

December is National Eggnog Month

Historians’ best guess as to the origin of eggnog dates back to the English Middle Ages, where a warm, milky ale called ‘posset’, was consumed. Posset was often consumed with eggs and figs; eggs, figs, dairy, and sherry were products that only the wealthy could afford to enjoy at the time. Eggnog was thought to have arrived in the U.S. prior to the revolutionary war. Whereas most of the eggnog consumed in Britain was by the upper class (with sherry), as eggnog advanced throughout the U.S. like a milky river of frothy delight, it was generally consumed with rum or bourbon.

Because the agricultural-based colonies were flush with chickens and cows, the consumption of eggnog was not limited to crusty upper class Brits, but rather a drink that most people throughout the American colonies could enjoy. In fact, food historian, Emelyn Rude (2015), author of “How Eggnog (Almost) Changed the World”, explains that consumption of eggnog was a popular holiday pastime of many, even including West Point cadets, such as Edgar Allen Poe and Jefferson Davis.

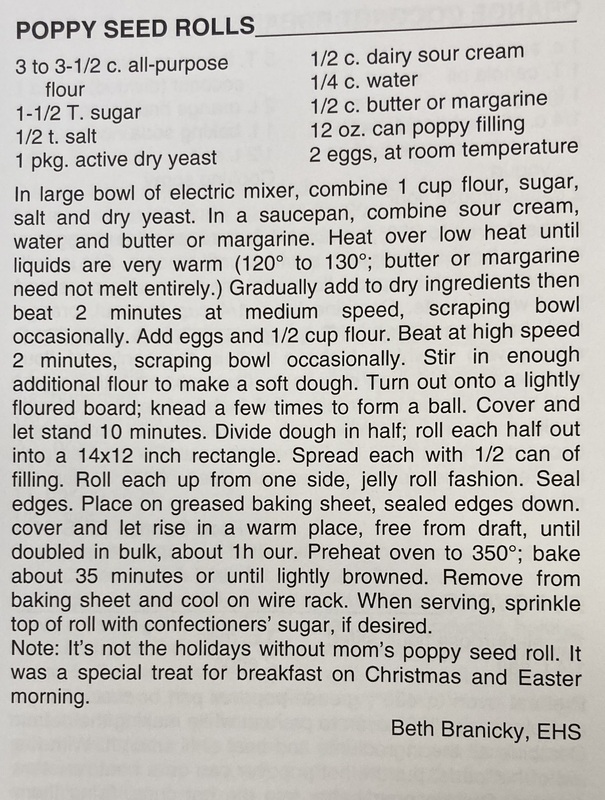

Makowiec

Makowiec is a poppy seed roll evolving from East European baking tradition that is commonly served during the Christmas season. It is a sweet pastry filled with a mixture of ground poppy seeds, honey, nuts, and sometimes raisins. The roll is often braided or shaped into a log and can be dusted with powdered sugar.

University of Michigan Slavic Languages and Literatures: Polish

Anna’s Food Blog: Polish Your Kitchen

Related:

Two square miles: The Evolution of Hamtramck as “Little Poland”

Womb Army: “How Hamtramck, a small town within Detroit, became America’s first Muslim-majority city”

How Hamtramck, a small town within Detroit, became America’s first Muslim-majority city https://t.co/62HOvETkUd

— Detroit Free Press (@freep) May 27, 2025

All That Remains:

Christ Chapel

“De re aedificatoria” | Leon Battista Alberti

Christianity is surging in America.

We will not become Europe.

— Eric Daugherty (@EricLDaugh) October 25, 2025

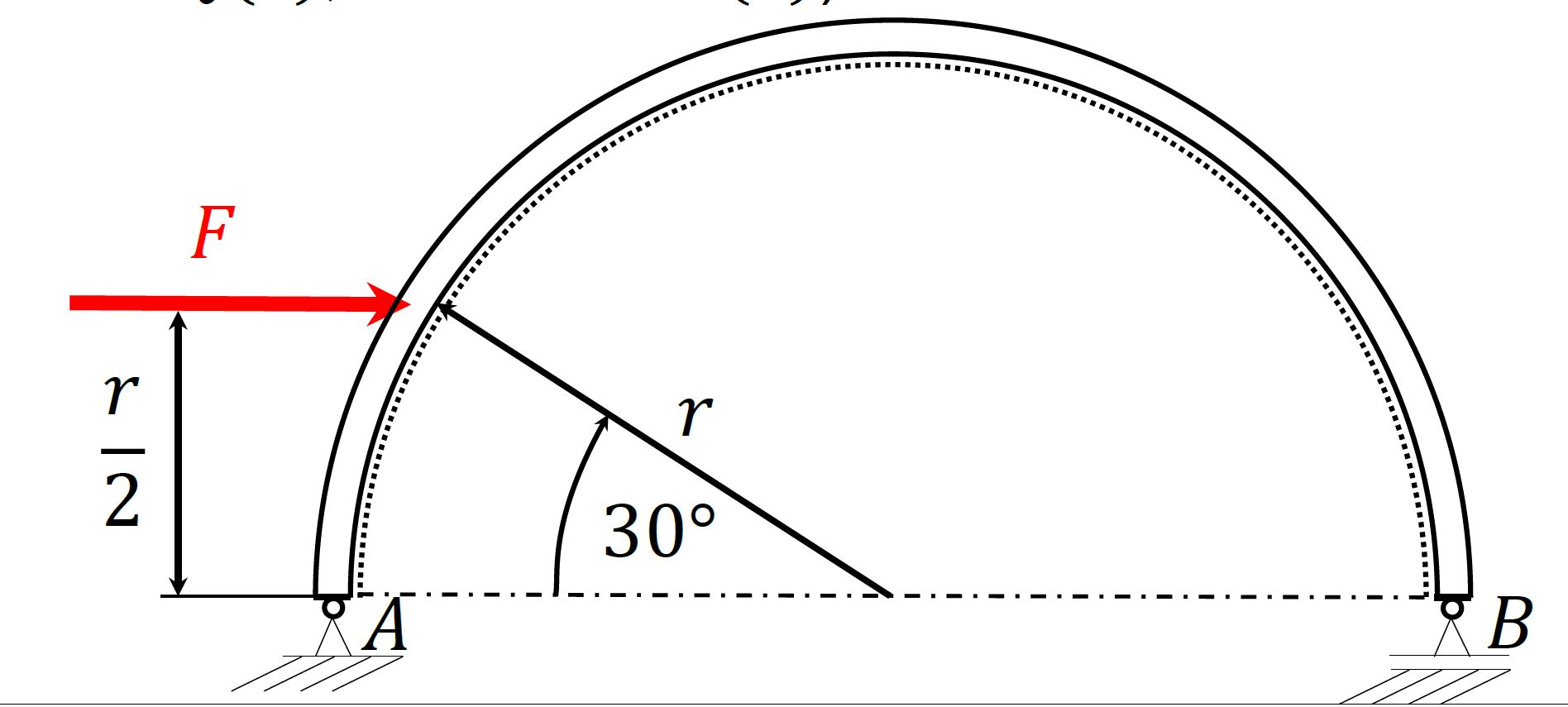

Compute the stress curves for the half-circular arch beam

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670