“The only emperor is the emperor of ice cream”

— Wallace Stevens

The invention of ice cream, as we know it today, is a product of historical evolution, and there isn’t a single individual credited with its creation. Various cultures and civilizations throughout history have contributed to the development of frozen treats resembling ice cream.

One of the earliest records of frozen desserts can be traced back to ancient China, where people enjoyed a frozen mixture of milk and rice around 200 BC. Similarly, ancient Persians and Arabs had a tradition of mixing fruit juices with snow or ice to create refreshing treats.

In Europe, frozen desserts gained popularity in the 17th and 18th centuries, and it was during this time that the more modern version of ice cream, made with sweetened milk or cream, began to take shape. During this period, ice cream became more widely accessible and enjoyed by the nobility and upper classes.

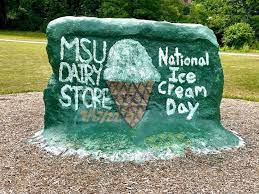

MSU Infrastructure Planning and Facilities

To produce ice cream on a commercial scale, several key pieces of infrastructure and equipment are necessary. The specific requirements may vary depending on the production capacity and the type of ice cream being produced, but the basic infrastructure typically includes:

- Manufacturing Facility: A dedicated space or building is needed to house all the production equipment and storage facilities. The facility should comply with local health and safety regulations and be designed to maintain the required temperature and hygiene standards.

- Mixing and Blending Equipment: Industrial-scale mixers and blending machines are used to mix ingredients like milk, cream, sugar, stabilizers, emulsifiers, and flavorings. These machines ensure that the mixture is homogenized and consistent.

- Pasteurization Equipment: To ensure product safety and extend shelf life, ice cream mix needs to be pasteurized. Pasteurization equipment heats the mixture to a specific temperature and then rapidly cools it to destroy harmful microorganisms.

- Homogenizers: Homogenizers help break down fat molecules in the ice cream mix to create a smoother and creamier texture.

- Aging Vats: The ice cream mix is aged at a controlled temperature for a specific period, which allows the ingredients to fully blend and improves the ice cream’s texture.

- Freezers: Continuous freezers or batch freezers are used to freeze the ice cream mix while incorporating air to create the desired overrun (the amount of air in the final product). Continuous freezers are more commonly used in large-scale production, while batch freezers are suitable for smaller batches.

- Hardening and Storage Room: Once the ice cream is frozen, it needs to be hardened at a lower temperature to achieve the desired texture. Storage rooms are used to store finished ice cream at the appropriate temperature until distribution.

- Packaging Equipment: Equipment for filling and packaging the ice cream into various containers, such as cartons, tubs, or cones.

- Quality Control and Laboratory Facilities: A dedicated area for quality control testing, where ice cream samples are analyzed for consistency, flavor, and other characteristics.

- Cleaning and Sanitation Systems: Proper cleaning and sanitation systems are essential to maintain hygiene and prevent contamination.

- Utilities: Adequate water supply, electrical power, and refrigeration capacity are critical for ice cream production.