Author Archives: mike@standardsmichigan.com

- Home

- Articles posted by mike@standardsmichigan.com (Page 44)

“Mountain High Apple Pie”

More than half of this year’s American Institute of Architects North Carolina (@AIA_NC) awards were won by @NCStateDesign students, faculty and alumni. 👏 Explore their projects: https://t.co/0J28nxhgC2 pic.twitter.com/ACpEgAQfsN

— NC State University (@NCState) January 19, 2024

North Carolina State University Facilities

Rhubarb Strawberry Pie

A dessert popular in the United Kingdom, where rhubarb has been cultivated since the 1600s, and the leaf stalks eaten since the 1700s. Besides diced rhubarb, it almost always contains a large amount of sugar to balance the intense tartness of the plant. The pie is usually prepared with a bottom pie crust and a variety of styles of upper crust.

In the United States, often a lattice-style upper crust is used. This pie is a traditional dessert in the United States. It is part of New England cuisine. Rhubarb has long been a popular choice for pies in the Great Plains region and the Michigan Great Lakes Region, where fruits were not always readily available in the spring

Related

University of Missouri: Plant rhubarb, the pie plant, in March

University of Nebraska: Rhubarb Cream Pie

TU Dublin: Rhubarb Pie Using Sweet Shortbread Pastry

Lemonade

Officer goes viral after response to ‘Mrs. Anonymous’ complaint over lemonade stand

“Thank you to “Mrs. Anonymous” for calling to complain about a kids’ lemonade stand. We responded and enjoyed a refreshing cup while making some new friends!” pic.twitter.com/WnkLgkyHZM

— Unlimited L’s (@unlimited_ls) July 30, 2025

University of Florida College of Agriculture and Life Sciences

More

United States Department of Agriculture: Frozen Concentrate for Lemonade Grades and Standards

United States Food & Drug Administration: Canned Fruit Juices

Spoon University: My Perfect Lemonade Recipe

Boathouses

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Easy Greek Salad

West Virginia University Financial Statement 2024 | $1.234B

We need your input 👋 If you frequent the dining halls (Cafe Evansdale, Hatfields and Summit Cafe) can you please take our satisfaction survey? It will only take a few minutes and will help shape the future of dining on campus.

➡️ https://t.co/7efJMbqeZ7 pic.twitter.com/ywKYxBe6GO

— WVU Dining (@WVUDining) April 22, 2024

Students: Be sure to stop by Café Evansdale from 11 a.m. to 1 p.m. today to meet Campus Dietitian Sina King and learn about the dietitian services available to WVU students. More info is available at: https://t.co/gxtKCIvMgy pic.twitter.com/D2VVEGGHFB

— WVU Dining (@WVUDining) August 23, 2022

Related:

Autumn Week 40 | September 29 – October 5

Monday | September 29 | Colloquium 15:00 UTC

Tuesday | September 30 | Colloquium 15:00 UTC

Wednesday | October 1 | Colloquium 15:00 UTC

Thursday | October 2 | Colloquium 15:00 UTC

“First the school, then the neighborhood.” Apart from safety codes, there are no standards as we work with them. But there are case studies

Friday | October 3 | Colloquium 15:00 UTC

Saturday | October 4

Sunday| October 5

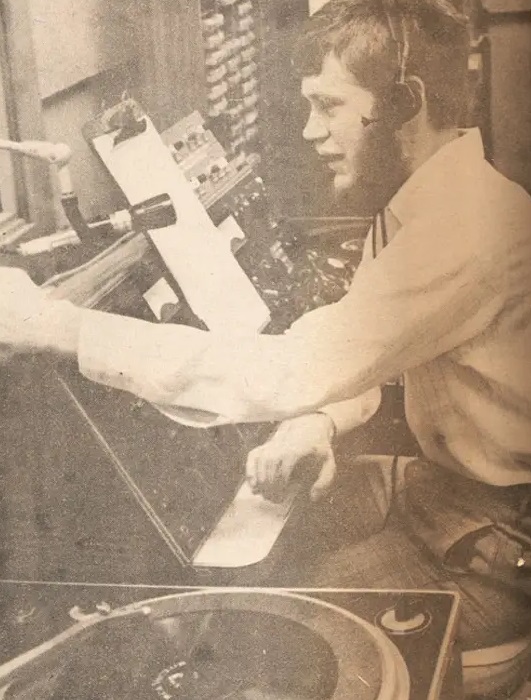

LIVESTREAM: WCRD 91.3FM

Ball State University was founded in 1918 and was originally named the Eastern Indiana Normal School and primarily a teacher’s college. The university was renamed Ball State University in 1965, in honor of the five Ball brothers, who began by manufacturing and selling wooden jacketed tin cans. In 1884, the company introduced the Ball Improved Mason Jar, which became a popular way to preserve food.

The university is home to the Center for Middletown Studies, which conducts research on the social and cultural dynamics of small-town America.

Moody’s Bond Rating Standard

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Malzkaffee

Chicory, surrogate and roasted coffee provide new insights into mechanisms of taste perception

Dr. Gisela Olias, Presse- und Öffentlichkeitsarbeit, TUM

In some Christian traditions, especially among Catholics who observe dietary restrictions during Lent, chicory root has been used as a caffeine-free substitute for coffee. It’s commonly consumed in Louisiana and parts of Europe.

The term “Muckefuck” (pronounced “Mook-eh-fook”) is a traditional German word for coffee substitutes, particularly those made from roasted chicory root, barley, or other grains. No joke! “Muckefuck” is a real historical term in Germany, and while it may sound funny to English speakers, it has nothing to do with profanity.

- The word likely comes from a mix of French and German dialects. One theory is that it originates from the French phrase “mocca faux”, meaning “fake coffee” (literally, “false mocha”).

- Over time, German pronunciation altered it into “Muckefuck”, referring to coffee substitutes made from chicory, barley, or other roasted grains.

- It was commonly used in Prussia, Bavaria, and other German-speaking areas, especially during times of war or economic hardship when real coffee was unavailable.

While the word may raise eyebrows for English speakers, it’s completely innocent in German! If you prefer, you can simply ask for “Chicorée Kaffee” or “Malzkaffee” in Munich to avoid any awkward moments.

Related:

Development of suitable formula for ready-to-drink healthy mixture of chicory and coffee

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670