Hubbell

- Home Page 106

Column 15

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Indoor Air Quality Design Tools for Schools

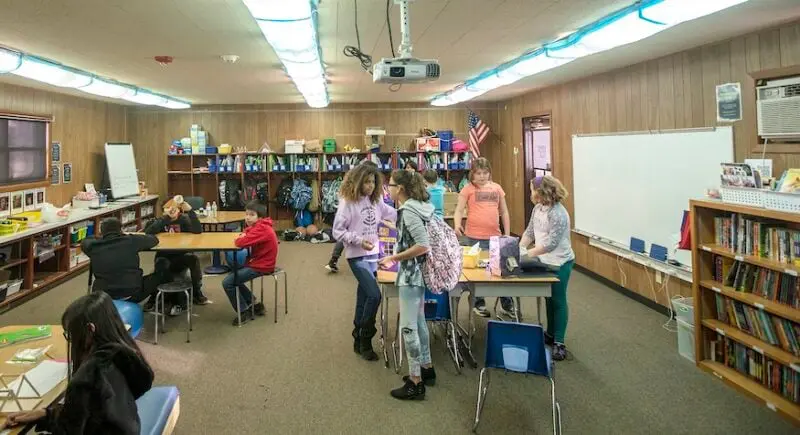

From a school district’s perspective, the two advantages of portable classrooms are low initial cost and short time between specification and occupancy. They are intended to provide flexibility to school districts, enabling quick response to demographic changes and providing the ability to be moved from one school to another as demographics change. In reality, portable classrooms are seldom moved and become permanent fixtures of the school.

A Modular Control Lab Equipment and Virtual Simulations for Engineering Education

A Modular Control Lab Equipment and Virtual Simulations for Engineering Education

Vanessa Young, et. al | Kennesaw State University Department of Mechanical Engineering

Abstract: Hands-on experiences in engineering education are highly valued by students. However, the high cost, large size, and non-portable nature of commercially available laboratory equipment often confine these experiences to lab courses, separating practical demonstrations from classroom teaching. Consequently, mechanical engineering students may experience a delay in practical engagement as lab sessions typically follow theoretical courses in subsequent semesters, a sequence that differs from mechatronics, electrical, and computer engineering programs. This study details the design and development of portable and cost-effective control lab equipment that enables in-class demonstrations of a proportional-integral-derivative (PID) controller for the trajectory and speed control of a DC motor using MATLAB Simulink, as well as disturbance control. The equipment, composed of a DC motor, beam, gears, crank, a mass, and propellers, introduces disturbances using either propellers or a rotating unbalanced mass. All parts of the equipment are 3D printed from polylactic acid (PLA). Furthermore, the beam holding the propellers can be attached to Quanser Qube lab equipment, which is widely used in control laboratories. The lab equipment we present is adaptable for demonstrations, classroom projects, or as an integral part of lab activities in various engineering disciplines.

Iced Caramel Macchiato

Home Page | Statement of Net Position 2024: $1,272B

Missing you, Beaver Nation 🧡 pic.twitter.com/XO4dhbL1c7

— Oregon State University (@OregonState) September 10, 2024

Brewvita

Liberty University Inc. Statement of Financial Position 2020: $3.936B, page 8

Comment what surprised you most about coming to Liberty!🔥 #College #LibertyUniversity #University #StudentLife pic.twitter.com/QyFdvjAWyo

— Liberty University (@LibertyU) July 3, 2025

Happy FDOC, Flames! 🔥 Whether you’re starting new courses today online or on our beautiful campus, we’re wishing you a strong start to a wonderful spring semester! 📚 pic.twitter.com/M0oMpCCNws

— Liberty University (@LibertyU) January 13, 2025

During Military Appreciation Month, we honored the brave men and women who have fought for our freedoms. Thank you to all servicemen, servicewomen, and veterans for your dedication and sacrifice for our country. 🇺🇸 pic.twitter.com/irii7hRmoy

— Liberty University (@LibertyU) November 26, 2024

The students have spoken — we’re having a hard time choosing only one favorite thing to do at LU! pic.twitter.com/GlTt0ugq8g

— Liberty University (@LibertyU) November 19, 2024

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670