Today, special attention to managing elevator passengers trapped in elevators during power outages. Incident management involves the following:

- Automatic battery-lowering systems (standard in modern elevators) gently descend the car to the nearest floor and open the doors within minutes.

- Backup generators or UPS units keep lights, intercoms, and ventilation running.

- Mandatory two-way communication and remote monitoring allow instant contact with 24/7 response teams.

- Fire-service phase II keys and firefighter overrides ensure rapid rescue.

- Clear emergency instructions and regular maintenance of brakes and overspeed governors prevent falls.

These redundancies, required by ASME A17.1 codes in most jurisdictions, have made prolonged entrapments extremely rare and almost never dangerous.

CMP-12 Public Input Transcript | CMP-12 Public Comment Transcript

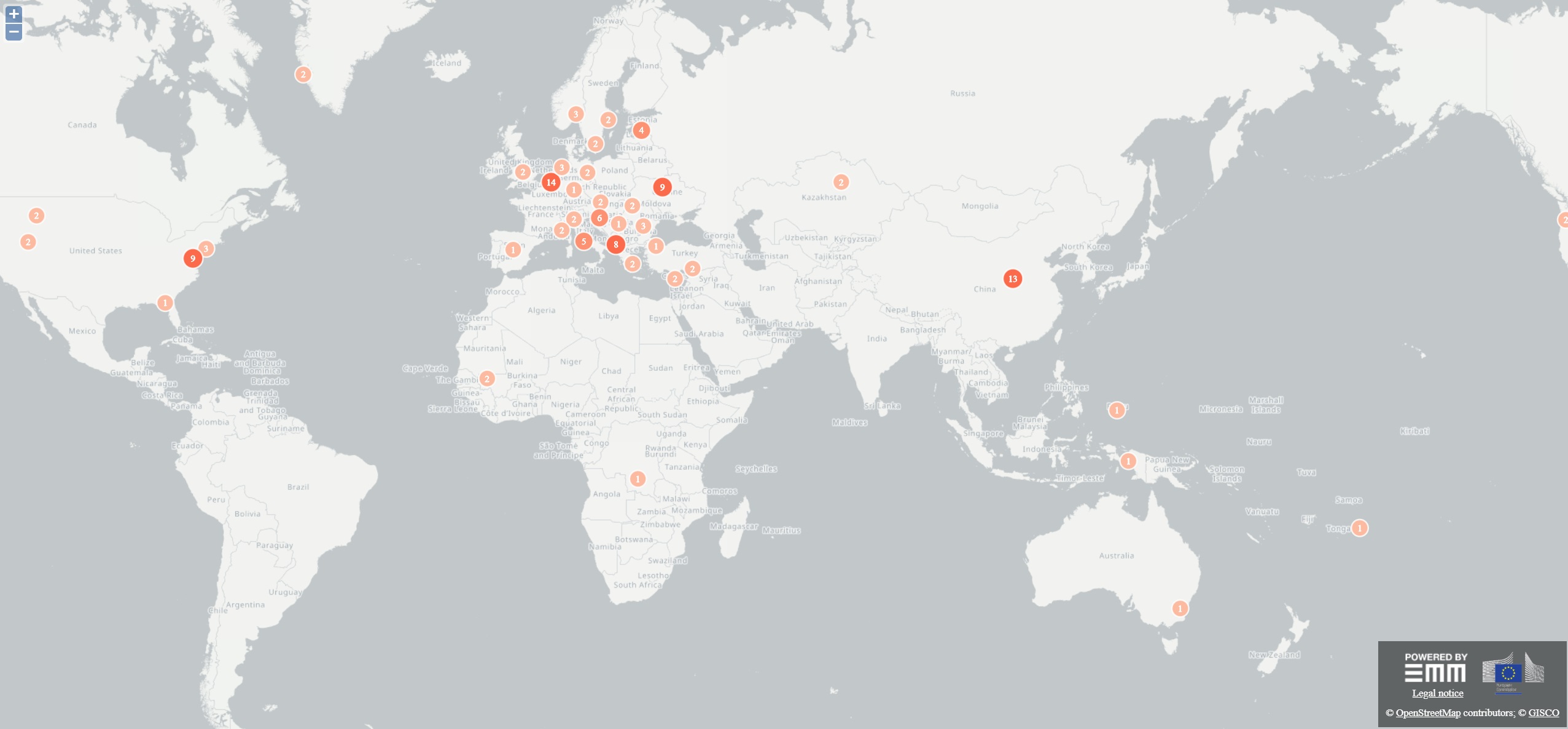

Elevator, escalator and moving walk systems are among the most complicated systems in any urban environment, no less so than on the #WiseCampus in which many large research universities have 100 to 1000 elevators to safely and economically operate, service and continuously commission. These systems are regulated heavily at state and local levels of government and have oversight from volunteers that are passionate about their work.

These “movement systems” are absorbed into the Internet of Things transformation. Lately we have tried to keep pace with the expansion of requirements to include software integration professionals to coordinate the interoperability of elevators, lifts and escalators with building automation systems for fire safety, indoor air quality and disaster management. Much of work requires understanding of the local adaptations of national building codes.

Some university elevator O&M units use a combination of in-house, manufacturer and standing order contractors to accomplish their safety and sustainability objectives.

In the United States the American Society of Mechanical Engineers is the dominant standards developer of elevator and escalator system best practice titles; its breakdown of technical committees listed in the link below:

C&S Connect: ASME Proposals Available for Public Review

Public consultation on a new standard for electrical inspector qualifications closes May 27th.

ASME A17.7/CSA B44.7 – 20XX, Performance-based code for elevators and escalators (280 pages)

Safety Code for Existing Elevators and Escalators

Guide for Inspection of Elevators, Escalators, and Moving Walks

Guide for Elevator Seismic Design

As always, we encourage facility managers, elevator shop personnel to participate directly in the ASME Codes & Standards development process. For example, it would be relatively easy for our colleagues in the Phoenix, Arizona region to attend one or more of the technical committee meetings; ideally with operating data and a solid proposal for improving the A17 suite.

All ASME standards are on the agenda of our Mechanical, Pathway and Elevator & Lift colloquia. See our CALENDAR for the next online teleconferences; open to everyone. Use the login credentials at the upper right of our home page.

Issue: [11-50]

Category: Electrical, Elevators, #WiseCampus

Colleagues: Mike Anthony, Jim Harvey, Richard Robben, Larry Spielvogel

More:

Bibliography: Elevators, Lifts and Moving Walks

ISO/TC 178 Lifts, escalators and moving walks