“The Church is not a gallery for the exhibition of eminent Christians,

but a school for the education of imperfect ones.”

— Henry Ward Beecher

WEBCAST Committee Action Hearings, Group A #2

2024 International Building Code: Chapter 3 Occupancy Classification and Use

In the International Code Council catalog of best practice literature we find the first principles for safety in places of worship tracking in the following sections of the International Building Code (IBC):

“303.1.4: Accessory religious educational rooms and religious auditoriums with occupant loads less than 100 per room or space are not considered separate occupancies.” This informs how fire protection systems are designed.

Section 305 Educational Group E

“305.2.1: Rooms and spaces within places of worship proving such day care during religious functions shall be classified as part of the primary occupancy.” This group includes building and structures or portions thereof occupied by more than five children older than 2-1/2 years of age who receive educational, supervision or personal care services for fewer than 24 hours per day.

Section 308 Institutional Group I

“308.5.2: Rooms and spaces within places of religious worship providing [Group I-4 Day Care Facilities] during religious functions shall be classified as part of the primary occupancy. When [Group I-4 Day Care Facilities] includes buildings and structures occupied by more than five persons of any age who receive custodial care for fewer than 24 hours per day by persons other than parents or guardians, relatives by blood, marriage or adoption, and in a place other than the home of the person cared for.

Tricky stuff — and we haven’t even included conditions under which university-affiliated places of worship may expected to be used as community storm shelters.

2024/2025/2026 ICC CODE DEVELOPMENT SCHEDULE

Public response to Committee Actions taken in Orlando in April will be received until July 8th.

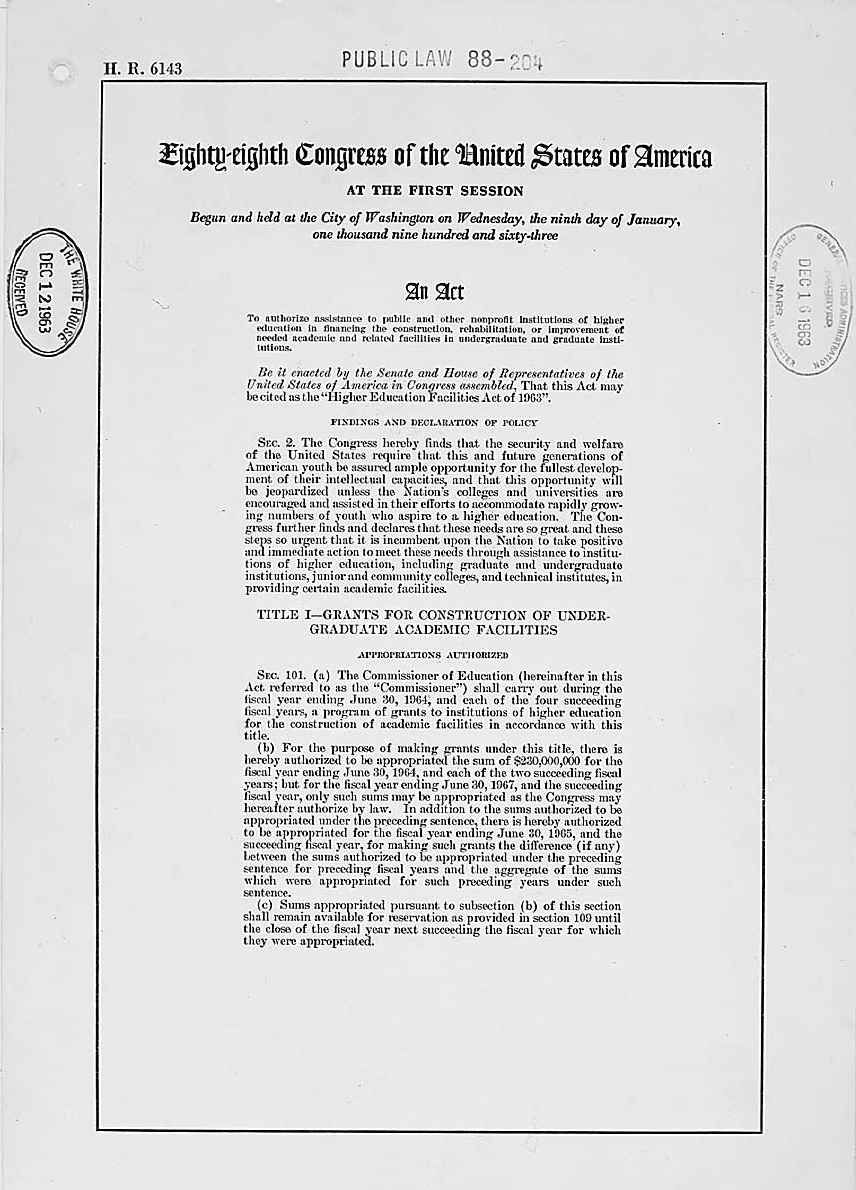

Because standard development tends to be a backward-looking domain it is enlightening to understand the concepts in play in previous editions. The complete monograph of proposals for new building safety concepts for places of worship for the current revision cycle is linked below:

2021/2022 Code Development: Group B

A simple search on the word “worship” will reveal what ideas are in play. With the Group B Public Comment Hearings now complete ICC administered committees are now curating the results for the Online Governmental Consensus Vote milestone in the ICC process that was completed December 6th. Status reports are linked below:

2018/2019 Code Development: Group B

Note that a number of proposals that passed the governmental vote are being challenged by a number of stakeholders in a follow-on appeals process:

A quick review of the appeals statements reveals some concern over process, administration and technical matters but none of them directly affect how leading practice for places of worship is asserted.

We are happy to get down in the weeds with facility professionals on other technical issues regarding other occupancy classes that are present in educational communities. See our CALENDAR for next Construction (Ædificare) colloquium open to everyone.

Issue: [17-353]

Category: Chapels

Colleagues: Mike Anthony, Jack Janveja, Richard Robben, Larry Spielvogel

More

Religion is a culture of faith; science is a culture of doubt. pic.twitter.com/H6dgJ5DnSC

— Prof. Feynman (@ProfFeynman) October 8, 2023