“Radio is the perfect medium for communication.

It is instantaneous, and unlike television,

it allows you to use your imagination.”

-Guglielmo Marconi

Tag Archives: December

- Home

- Posts tagged "December"

LIVE: 91.3 FM Cal Poly Student Radio

Schenkingen

“The secret of great fortunes without apparent cause

is a crime forgotten, for it was properly done.”

Are they hedge funds with a side hustle in teaching, research and building construction? Are they tricked out memorial gardens for philanthropists? In either case leaders of educational settlements are expected to act in the best interests of both their institution and their donors, and to maintain high standards of transparency, accountability, and ethical conduct when accepting charitable gifts.

University endowments are comprised of money or other financial assets that are donated to academic institutions. Charitable donations are the primary source of funds for endowments. Endowment funds support the teaching, research, and public service missions of colleges and universities.

In the case of endowment funds for academic institutions, the income generated is intended to finance a portion of the operating or capital requirements of the institution. In addition to a general university endowment fund, institutions may also maintain a number of restricted endowments that are intended to fund specific areas within the institution, including professorships, scholarships, and fellowships.

More

2021 NACUBO-TIAA Study of Endowments

University of Michigan: Policy Guidelines for Naming of Facilities, Spaces and Streets

Dartmouth University Endowment Report 2023

https://www.dartmouth.edu/investments/docs/dartmouthendowmentreport2023.pdf

The largest philanthropic gift ever given to a United States college or university is the donation of $9.6 billion made by MacKenzie Scott to various organizations, including several universities, in 2020. Scott, the ex-wife of Amazon founder Jeff Bezos, made the donation as part of her commitment to give away the majority of her wealth to charitable causes. The universities that received donations from Scott include historically black colleges and universities, community colleges, and research universities such as the University of California, San Diego, and Johns Hopkins University. The donation was considered significant not only for its size but also for its focus on supporting organizations that serve underrepresented and marginalized communities.

There are several standards and best practices that are generally followed by universities and colleges when accepting charitable gifts. These standards are designed to ensure that the gift is used effectively and that the interests of both the donor and the institution are protected. Some of the key standards include:

- Transparency and accountability: Universities and colleges are expected to be transparent about how gifts are used and to provide regular reports to donors on the impact of their gifts.

- Due diligence: Universities and colleges are expected to conduct due diligence on potential donors to ensure that their gifts do not create conflicts of interest or ethical concerns.

- Gift acceptance policies: Many universities and colleges have established gift acceptance policies that outline the types of gifts that will be accepted and the procedures for accepting them.

- Donor recognition: Universities and colleges are expected to recognize donors in an appropriate and meaningful way, while avoiding actions that could be seen as an endorsement of the donor’s business or political interests.

- Ethical fundraising: Universities and colleges are expected to follow ethical fundraising practices, including avoiding pressure tactics or misleading information, and ensuring that donors are aware of any tax implications of their gifts.

Overall, universities and colleges are expected to act in the best interests of both their institution and their donors, and to maintain high standards of transparency, accountability, and ethical conduct when accepting charitable gifts.

Designing Lighting for People and Buildings

IES Standards Open for Public Review

Standard Practice on Lighting for Educational Facilities

Recommended Practice: Lighting Retail Spaces

IES Method for Determining Correlated Color Temperature

Today we feature the catalog of the Illumination Engineering Society — one of the first names in standards-setting in illumination technology, globally* with particular interest in its leading title IES LP-1 | LIGHT + DESIGN Lighting Practice: Designing Quality Lighting for People and Buildings.

From its prospectus:

“…LIGHT + DESIGN was developed to introduce architects, lighting designers, design engineers, interior designers, and other lighting professionals to the principles of quality lighting design. These principles; related to visual performance, energy, and economics; and aesthetics; can be applied to a wide range of interior and exterior spaces to aid designers in providing high-quality lighting to their projects.

Stakeholders: Architects, interior designers, lighting practitioners, building owners/operators, engineers, the general public, luminaire manufacturers. This standard focuses on design principles and defines key technical terms and includes technical background to aid understanding for the designer as well as the client about the quality of the lighted environment. Quality lighting enhances our ability to see and interpret the world around us, supporting our sense of well-being, and improving our capability to communicate with each other….”

The entire catalog is linked below:

Illumination technologies run about 30 percent of the energy load in a building and require significant human resources at the workpoint — facility managers, shop foremen, front-line operations and maintenance personnel, design engineers and sustainability specialists. The IES has one of the easier platforms for user-interest participation:

IES Standards Open for Public Review

Because the number of electrotechnology standards run in the thousands and are in continual motion* we need an estimate of user-interest in any title before we formally request a redline because the cost of obtaining one in time to make meaningful contributions will run into hundreds of US dollars; apart from the cost of obtaining a current copy.

We maintain the IES catalog on the standing agendas of our Electrical, Illumination and Energy colloquia. Additionally, we collaborate with experts active in the IEEE Education & Healthcare Facilities Committee which meets online 4 times monthly in European and American time zones; all colloquia online and open to everyone. Use the login credentials at the upper right of our home page to join us.

Issue: [Various}

Category: Electrical, Energy, Illumination, Facility Asset Management

Colleagues: Mike Anthony, Gary Fox, Jim Harvey, Kane Howard, Glenn Keates, Daleep Mohla, Giuseppe Parise, Georges Zissis

* “Brownian Motion” comes to mind because of the speed and interdependencies.

LEARN MORE:

Illuminating Engineering Society Welcomes New Director of Development

Shayna Bramley Brings 21 years of Lighting Industry Experience to IESTo learn more, to go: https://t.co/YApdTPvR8E pic.twitter.com/PGDCtO4jrC

— Illuminating Engineering Society (@The_IES) December 26, 2018

The LD+A editorial and sales team members just couldn’t resist visiting Bugsy and Meyer’s Steakhouse (covered in the December 2021 issue) while in Las Vegas for LightFair! Read up on the details of the shadowy project here: https://t.co/7eoLPT69Dx #TheIES #LightFair2022 #lighting pic.twitter.com/uWmolsNpMz

— Illuminating Engineering Society (@The_IES) June 22, 2022

Observatories & Planetariums

“I know that I am mortal by nature, and ephemeral;

but when I trace at my pleasure the windings to and fro of the heavenly bodies,

I no longer touch Earth with my feet:

I stand in the presence of Zeus himself and take my fill of ambrosia.”

— Ptolemy, “Mathematike Syntaxis” 150 A.D

Planetariums in schools and colleges play a central in enhancing astronomy and astrophysics education. They provide immersive experiences that can ignite students’ interest and curiosity about the universe, making complex astronomical concepts more comprehensible and engaging. Observatories do much that but with direct access to telescopes and other observational tools — frequently away from campus — thus allowing them to engage in hands-on learning and real-time data collection.

Establishing research and teaching programs present special occupancy challenges. The cost of high-quality telescopes and equipment, along with the need for a suitable location with minimal light pollution, can be substantial. Additionally, schools require trained staff to guide students in using the equipment and interpreting data. Weather conditions and geographical location also impact the effectiveness of observatories. Despite these hurdles, the educational value of observatories is immense, providing students with unique opportunities to explore the universe and cultivate a passion for scientific inquiry.

Today we examine both occupancies using our SAFER-SIMPLER-LOWER COST-LONGER LASTING discipline. Use the login credentials at the upper right of our home page at the usual hour.

Purdue University: Grand Universe planning liftoff in Hamilton County

The International Building Code includes various sections that address safety requirements relevant to observatories and planetariums. Key parts of the IBC that cover these requirements include:

- Chapter 3: Use and Occupancy Classification

- Section 303: Assembly Group A. Planetariums and observatories often fall under Assembly Group A due to their function as places where people gather for educational and entertainment purposes. Specific occupancy types and associated requirements will be detailed here.

- Chapter 4: Special Detailed Requirements Based on Use and Occupancy

- Section 410: Stages, Platforms, and Technical Production Areas. While not specific to planetariums, this section provides guidance on assembly spaces, which may be applicable to the design and safety considerations for the auditorium areas in planetariums.

- Chapter 11: Accessibility

- Section 1103: Scoping Requirements. This section ensures that buildings are accessible to individuals with disabilities, which is crucial for public facilities like planetariums and observatories.

- Section 1104: Accessible Routes. Requirements for accessible paths to ensure ease of access to and within the facility.

- Chapter 12: Interior Environment

- Section 1203: Ventilation. Adequate ventilation is essential in enclosed spaces like planetariums to ensure air quality and comfort.

- Section 1205: Lighting. Ensuring appropriate lighting levels and types, which is crucial in areas like control rooms and observational spaces.

- Chapter 15: Roof Assemblies and Rooftop Structures

- Section 1509: Rooftop Structures. Covers the installation and safety of rooftop observatories, which can include structural requirements and access considerations.

- Chapter 16: Structural Design

- Section 1604: General Design Requirements. Ensures that the structure can support both the static and dynamic loads associated with heavy equipment like telescopes.

- Section 1607: Live Loads. Specific load requirements for observatory equipment and public assembly areas.

These chapters collectively ensure that planetariums and observatories are designed and constructed with safety, accessibility, and functionality in mind. For detailed information, it is recommended to refer to the latest edition of the IBC and consult with a professional knowledgeable in building codes and standards.

World Astronomy Day is Saturday, and to celebrate we are showing off some of our favorite pictures of the Albion College Observatory. The Albion College Observatory was constructed from 1883-1884 under the direction of Dr. Samuel Dickie. #ThrowbackThursday #TBT #MyAlbion pic.twitter.com/ixgtAMlP4z

— Albion College (@albioncollege) May 13, 2021

Designing and building a telescope for teaching and light research at a college or university requires a detailed consideration of both the telescope itself and the supporting infrastructure. Here are the central architectural features:

Telescope Structure:

- Optical System:

- Aperture Size: A medium to large aperture (typically 0.5 to 1.5 meters) to gather sufficient light for educational and light research purposes.

- Type of Telescope: Reflecting (Newtonian, Cassegrain, or Ritchey-Chrétien) or refracting telescope, chosen based on specific educational and research needs.

- Mount: A sturdy, precise mount (equatorial or alt-azimuth) to support the telescope and ensure smooth tracking of celestial objects.

- Enclosure:

- Dome or Roll-Off Roof: A protective structure to house the telescope, with a retractable roof or dome to allow for unobstructed viewing.

- Material: Weather-resistant materials such as aluminum or fiberglass, designed to protect the telescope from the elements.

- Control Systems:

- Computerized Controls: For automatic tracking and alignment of celestial objects, often including software for scheduling and managing observations.

- Remote Operation Capabilities: Allowing students and researchers to control the telescope remotely for data collection and analysis.

Support Infrastructure:

- Observation Deck:

- Viewing Platforms: Elevated platforms around the telescope for students to observe through the telescope and participate in hands-on learning.

- Safety Features: Railings and non-slip surfaces to ensure safety during nighttime observations.

- Control Room:

- Location: Adjacent to the telescope enclosure, with visibility to the telescope for direct supervision.

- Equipment: Computers, monitors, data storage, and communication equipment to control the telescope and process observational data.

- Classroom and Lab Spaces:

- Multipurpose Rooms: For lectures, demonstrations, and data analysis related to astronomy and telescope use.

- Laboratory Equipment: Spectrometers, cameras, photometers, and other instruments for conducting light research and analyzing data collected from the telescope.

- Data Processing and Storage:

- Computing Facilities: High-performance computers and software for analyzing astronomical data.

- Data Storage Solutions: Secure and scalable storage for large volumes of observational data.

- Accessibility Features:

- Elevators and Ramps: To provide access to all areas of the facility, including the observation deck and control room.

- Adapted Equipment: Adjustable eyepieces and controls to accommodate users with disabilities.

- Lighting:

- Red Lighting: Low-intensity red lights for night-time use to preserve night vision while allowing safe movement.

- Exterior Lighting: Shielded lighting around the facility to minimize light pollution and ensure optimal observing conditions.

By integrating these architectural features, a college or university can create a functional and effective observatory that supports both teaching and light research in astronomy.

University of Michigan | Detroit Observatory

Designing and building a planetarium for public use involves careful consideration of various architectural features to ensure functionality, aesthetics, and a positive visitor experience. Here are the central architectural features required:

- Dome Structure:

- Shape and Size: The dome must be a perfect hemisphere to provide an unobstructed view of the projected sky. The size should be large enough to accommodate the intended audience while ensuring good visibility from all seating positions.

- Material: Typically constructed from aluminum or fiberglass, with an inner surface coated to enhance the projection quality.

- Projection System:

- Projectors: High-resolution digital projectors or traditional optical-mechanical projectors are essential for displaying realistic night skies, astronomical phenomena, and educational shows.

- Sound System: High-quality surround sound systems to complement visual projections, enhancing the immersive experience.

- Seating Arrangement:

- Tilted Seats: Reclined and tiered seating ensures all viewers have an unobstructed view of the dome.

- Accessibility: Include spaces for wheelchairs and accessible seating to accommodate all visitors.

- Control Room:

- Location: Typically located at the rear or side of the planetarium for ease of access and control.

- Equipment: Houses computers, projection equipment, sound systems, and control panels for show operations.

- Entrance and Exit Points:

- Flow Management: Design multiple entrances and exits to manage the flow of visitors efficiently and safely, avoiding congestion.

- Accessibility: Ensure entrances and exits are accessible for all, including ramps and elevators as needed.

- Lobby and Reception Area:

- Ticketing and Information Desks: Central area for purchasing tickets, obtaining information, and gathering before shows.

- Displays and Exhibits: Interactive exhibits and displays related to astronomy and science to engage visitors while they wait.

- Lighting:

- Adjustable Lighting: Capability to control lighting levels to facilitate different show requirements, including complete darkness for optimal viewing.

- Safety Lighting: Emergency lighting and pathway lights for safe movement in low-light conditions.

- Climate Control:

- HVAC Systems: Efficient heating, ventilation, and air conditioning to maintain a comfortable environment for visitors and protect sensitive equipment.

- Acoustic Design:

- Soundproofing: Proper insulation and soundproofing to ensure external noise does not disrupt shows and internal sound is clear.

- Acoustic Treatment: Materials and design features to enhance sound quality and reduce echoes within the dome.

- Educational and Interactive Spaces:

- Classrooms and Labs: Spaces for educational programs, workshops, and hands-on activities related to astronomy.

- Interactive Kiosks: Digital kiosks with interactive content to engage visitors in learning about astronomy and space science.

- Accessibility Features:

- Elevators and Ramps: For easy access to different levels of the planetarium.

- Signage and Information: Clear signage in multiple languages and formats (e.g., braille) to assist all visitors.

- Exterior Design:

- Aesthetic Appeal: The exterior should be inviting and reflect the scientific and educational purpose of the planetarium.

- Landscaping: Incorporate outdoor spaces, such as gardens or open-air exhibits, that complement the planetarium experience.

- Parking and Transportation:

- Ample Parking: Provide sufficient parking spaces, including spots for buses and accessible parking.

- Public Transit Access: Ensure the planetarium is accessible via public transportation for the convenience of all visitors.

These architectural features are essential to create a functional, welcoming, and educational environment in a planetarium for public use.

Fiske Planetarium

The largest planetarium on a U.S. college or university campus is the Fiske Planetarium at the University of Colorado Boulder. The Fiske Planetarium features a 65-foot diameter dome and has undergone significant technological upgrades, making it one of the most advanced planetariums in the country. It offers a variety of shows, including live demonstrations and immersive experiences that simulate different cosmic phenomena and environments (CU Connections).

Gallery: Graduation Commencement Speeches

“It is at leaving the college and entering the world that the education of youth begins…

It is less uniform than that of childhood but more dependent on chance, and doubtless more important.

The youth is then attacked by a greater number of sensations: all that surrounds him strikes him,

and strikes him forcibly.”

— Claude-Adrien Helvétius (A Treatise on Man)

Constructor University (formerly, Jacobs University Bremen Germany) Graduation Band: “Freebird”

Intercollegiate Studies Institute | What Makes the West Strong (Sir Roger Scruton)

Dahlgren Hall & “Seasoned” Coffee Mug Stories

Named after Rear Admiral John A. Dahlgren (1809-1870) an influential figure in the development of naval ordnance during the United States Civil War. It served as an armory and drill hall for midshipmen. Its open space was ideal for indoor drills and military exercises.

The hall was constructed between 1899 and 1903. Its design was overseen by Ernest Flagg, a prominent architect who designed several buildings at the Naval Academy. Today it houses the Drydock Restaurant, a gathering place for midshipmen, faculty, and visitors.

Turkey Pot Pie Soup

Cornell University Dining: Student & Campus Life

Ingredients:

- 1/4 cup flour

- 2 cups turkey stock

- 4 cups fat free milk

- 2 large celery stalks, chopped

- 1 1/2 cups chopped onion

- 8 oz sliced cremini mushrooms

- Salt and pepper to taste

- 2 Tablespoons chopped parsley

- 8 oz frozen peas and carrots

- 1 teaspoon turkey bullion

- 2 medium potatoes, cubed small

- 16 oz cooked turkey breast, diced small or shredded

Directions:

- 1.Create a slurry by combining 1/2 cup of the cold broth with flour in a medium bowl and whisk until well blended. Set aside.

- 2.Pour remaining broth and milk into a large pot and slowly bring to a boil.

- 3.Add celery, onion, mushrooms, parsley, fresh pepper, frozen vegetables, and bullion, and return to a boil. Partially cover and simmer on low until vegetables are soft, about 20 minutes.

- 4.Remove lid, add potatoes and cook until soft, about 5 minutes.

- 5.Add turkey, and slowly whisk in slurry, stirring well as you add. Cook another 2-3 minutes, until soup thickens, adjust salt and pepper to taste and serve.

*Recipe from Skinny Taste

Nutrition Information: 1 1/3 cups| servings per recipe: 8 | Calories: 192, total fat: 2 g, saturated fat: 0 g, trans fat: 0 g; cholesterol: 1.3 mg, sodium: 159 mg, carbohydrates: 27 g, fiber: 8.3 g, sugar: 8.5 g, protein: 18 g

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

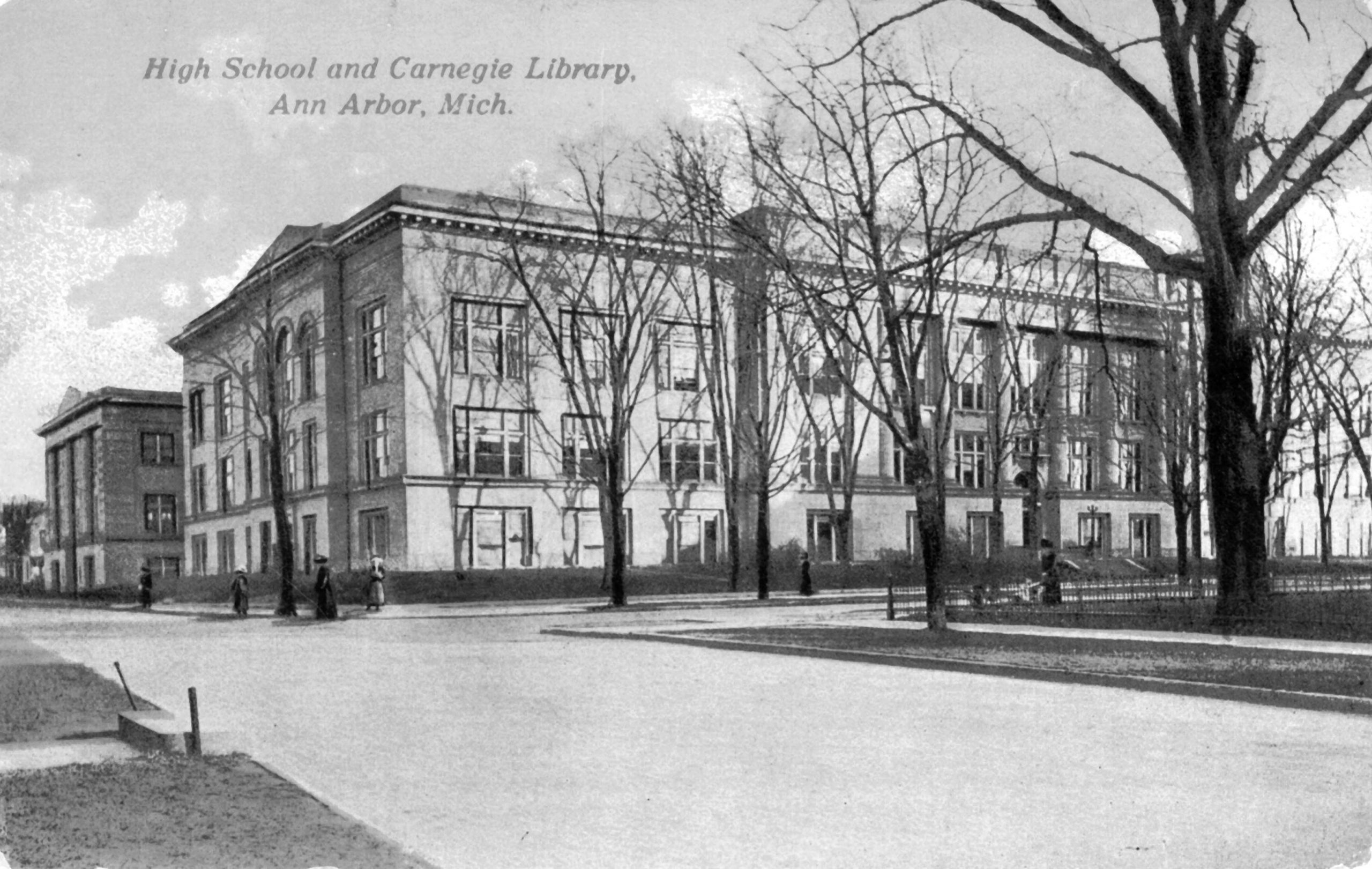

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670