Related:

NIST Grant by Paul Green, University of Michigan

ARCHIVED (Ross Business School Media): University of Michigan Business School | ANSI CEO S. Joe Bhatia | October 2014

Related:

NIST Grant by Paul Green, University of Michigan

ARCHIVED (Ross Business School Media): University of Michigan Business School | ANSI CEO S. Joe Bhatia | October 2014

At one Christendom College, the average student has six siblings—more than any college in America.

No coincidence they also just built the most beautiful chapel on campus.

Life and beauty go hand in hand. pic.twitter.com/JkbEQbTBfP— Jeremy Wayne Tate (@JeremyTate41) July 25, 2025

If you want a faithful Catholic college education for your children in the United States, I would suggest Christendom College in Virginia, which Justice Clarence Thomas referred to as a “decidedly Catholic college.”

Website: https://t.co/i6SvHu0Gz1

Follow: @ChristendomVA— Sachin Jose (@Sachinettiyil) July 30, 2025

“De re aedificatoria” | Leon Battista Alberti

Christianity is surging in America.

We will not become Europe.

— Eric Daugherty (@EricLDaugh) October 25, 2025

Compute the stress curves for the half-circular arch beam

Eero Saarinen‘s MIT Chapel is widely regarded as a masterpiece of modernist architecture and has been praised by architectural critics for its innovative design and spiritual atmosphere. Here are some examples of what critics have written about the chapel:

Ada Louise Huxtable, writing in The New York Times in 1955, described the chapel as a “sacred space of rare and exceptional quality” and praised its “dramatic contrasts of light and dark, scale and detail, intensity and serenity.”

Vincent Scully, writing in Architectural Forum in 1956, called the chapel “a consummate work of art” and praised Saarinen’s use of light and form to create a “subtle and mysterious” atmosphere.

Reyner Banham, writing in New Society in 1964, described the chapel as “an object of timeless quality” and praised its “radiant luminescence” and “clear and quiet” spatial qualities.

Paul Goldberger, writing in The New York Times in 2003, called the chapel “one of the great architectural treasures of the 20th century” and praised its “perfectly balanced” combination of light, color, and texture.

Overall, critics have praised the MIT Chapel for its innovative design, its spiritual atmosphere, and its skillful use of light and form. The chapel is considered one of Saarinen’s most important works and a landmark of modernist architecture.

Our Short Documentary: Meral Ekincioglu, Ph.D

Interview: David Adjaye at MIT

International Existing Building Code

Encourages the use and reuse of existing buildings. This code covers repair, alteration, addition and change of occupancy for existing buildings. and historic buildings, while achieving appropriate levels of safety without requiring full compliance with the new construction requirements contained in the other I-Codes. Key changes in the 2021 IEBC® include:

Religion is a culture of faith; science is a culture of doubt. pic.twitter.com/H6dgJ5DnSC

— Prof. Feynman (@ProfFeynman) October 8, 2023

Montclair State University Financial Position: $391, 445 (000)

New Jersey Schools Development Authority: Design Standards

The European Conservative: Harrison Pitt & Eric Kaufman

Wishing it could be fall year round 🍂 #MontclairViews pic.twitter.com/l1J5ybZ2g5

— Montclair State University (@montclairstateu) October 23, 2025

Related:

Public Input on the 2029 Edition will be received until January 6, 2027

“Wir haben Kunst, damit wir nicht

an der Wahrheit zugrunde gehen”

Not every student is passionate about Graph Algorithms, Green Policy or coding the Internet of Things but wants to devote their energy and talent to making the world a better place by making the world a more beautiful place. Spaces for the “creatives” among them are elevated risk spaces. Today we examine the literature for designing, building and maintaining these occupancies in the safest and most sustainable way; among them the spaces for textile research and fashion design; usually co-mingled with drawing, painting, and textile creation space.

The garment industry is multi-disciplinary and is larger than the energy industry. It contributes to the standard for civilization; even though subtly so. For this reason, starting 2023, we will break down our coverage of the literature that supports the fashion industry from the fine arts domain in separate colloquia every quarter.

Fine Arts 200. Exploration of best practice for spaces used for various forms of creative expression that are appreciated for their artistic or aesthetic value, often involving skills and techniques that require specialized training and expertise.

Fashion 300. Best practice literature for the spaces needed for the creation of artworks using textiles and fibers, such as weaving, quilting, or embroidery. Research and teaching spaces in this domain; at the foundation of the garment industry — one of the largest sectors in the economy in any nation — present surprising challenges

See our CALENDAR for a schedule of those session.

US-based standards developers with a footprint in the fine arts domain:

Committee D13 on Textiles Celebrates a Century

2021 International Building Code: Section 305 Educational Group E

Underwriters Laboratories

Lorem ipsum (product testing: kiln heat specifications, fabric and paint flammability, wet and dry fire extinguishing systems, etc.)

National Fire Protection Association

Institute of Electrical and Electronic Engineers

Leveraging User-Provided Noisy Labels for Fashion Understanding

Institutional Guidelines

Federal Regulations & Recommendations

Environmental Health and Safety in the Arts Guide for K-12 School, Colleges and Artisans

Global standard developers: (partial list)

Open to everyone. Use the login credentials at the upper right of our home page.

🌤️🌺⛲🌳 pic.twitter.com/bRL7eIY4gg

— Cranbrook Academy of Art (@cranbrookart) July 3, 2023

More

Texas Education Agency: Fine Arts Standards

Texas Tech: Facilities Planning & Construction

“Public art is form of street life, a means to articulate the implicit values of a city when its users occupy the place of determining what the city is.” — Malcolm Miles

Law & Crime Network: Bizarre Details of Louvre Heist That Shocked the World

Several universities host federal enterprises (laboratories, wildlands, Presidential libraries*, etc.) that must conform to Title 40 United States Code, Public Buildings, Property, and Works Paragraph 486(c) provides statutory authority for the head of each executive agency to issue orders and directives necessary to manage the Government’s property.

Code of Federal Regulations (CFR) 41 Federal Property Management Regulations Part 101, Subpart 20.5 “Physical Protection”, prescribes policies and methods for physically protecting buildings and grounds operated by GSA and other Federal Executive agencies. The Department of the Interior’s property management regulations are in Part 114 of CFR 41.

Museum Management Chapter 14: Museum Collections Security

Standard Methods of Fire Tests for Flame Propagation of Textiles and Films

* There are only a few education communities that host Presidential Libraries:

Herbert Hoover Presidential Library and Museum – West Branch, Iowa (Hoover Institution, Stanford University)

Lyndon B. Johnson Presidential Library and Museum – Austin, Texas (The University of Texas at Austin)

Gerald R. Ford Presidential Library and Museum – Ann Arbor, Michigan (The University of Michigan)

George H. W. Bush Presidential Library and Museum – College Station, Texas (Texas A&M University)

Public Input on the 2029 Edition will be received until January 6, 2027

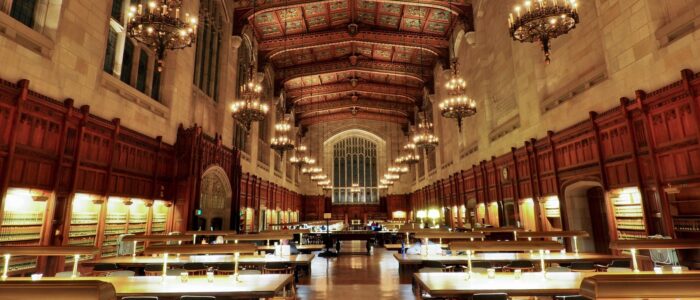

Books cannot be killed by fire. People die, but books never die

No man and no force can put thought in a concentration camp forever

— Franklin Roosevelt

Many education communities build and maintain cultural resource properties whose safety and sustainability objectives are informed by local adaptations of consensus products developed by the International Code Council (ICC) and the National Fire Protection Association (NFPA). We need to understand the ICC and NFPA product suites as a pair. For most real assets in the education industry they move “roughly” in tandem even though they are produced by different organizations for a different set of customers. Sometimes the out-of-step condition between NFPA and ICC permits subject matter experts on technical committees to make the best possible decisions regarding the safety and sustainability agenda of the interest group they represent; but not always.

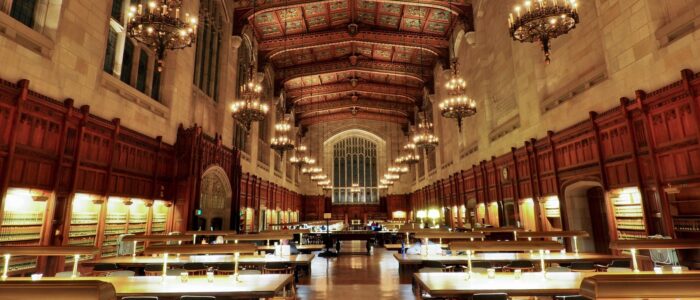

Occupancy classification is always a first consideration and both the NFPA and the ICC have a claim to some part of this occupancy concept*. In the ICC suite we find code requirements for many “cultural places of worship” tracking in the following sections of the International Building Code (IBC):

Section 303 Assembly Group A-3

Section 305 Educational Group E

Section 308 Institutional Group I

Note that Sections 305 and 308 recognize the accessory and multi-functional nature of occupancy types in the education industry – i.e child care and adult care function can marge and be an accessory to a place of worship. The general rule in the IBC is that accessory religious educational rooms and religious auditoriums with occupant loads of less than 100 per room or space are not considered separate occupancies. Other standards developers are guided by this rule.

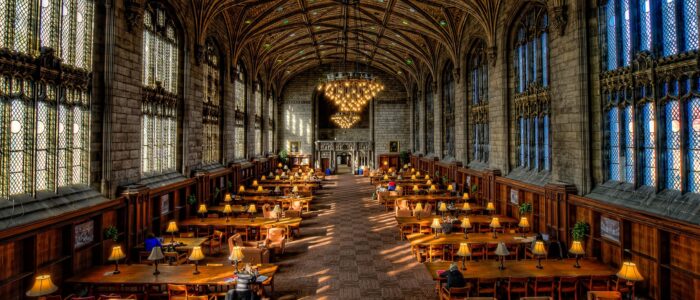

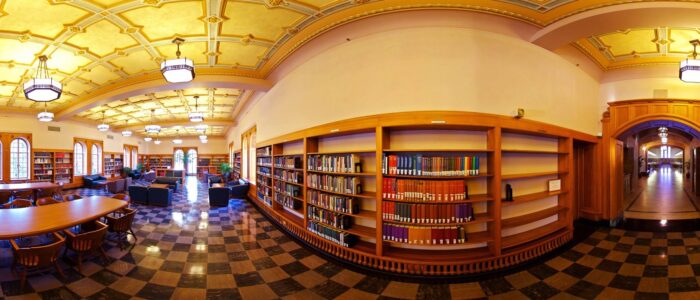

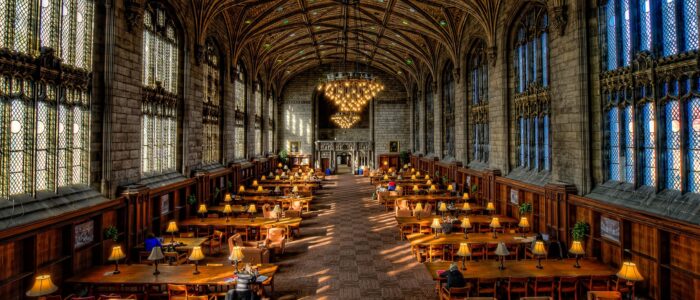

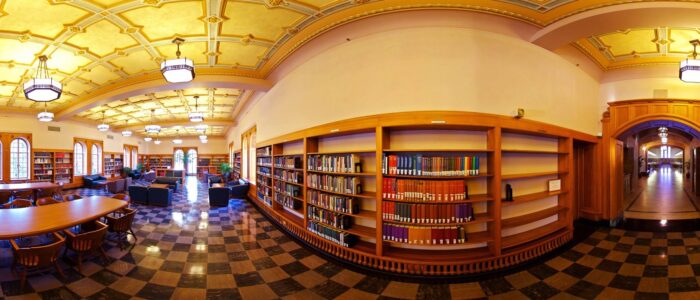

Close coupled to the IBC for this occupancy class is NFPA 909 Code for the Protection of Cultural Resource Properties – Museums, Libraries, and Places of Worship. From the document prospectus:

• This code describes principles and practices of protection for cultural resource properties (including, but not limited to, museums, libraries, and places of worship), their contents, and collections, against conditions or physical situations with the potential to cause damage or loss.

• This code covers ongoing operations and rehabilitation and acknowledges the need to preserve culturally significant and character-defining building features and sensitive, often irreplaceable, collections and to provide continuity of operations.

• Principles and practices for life safety in cultural resource properties are outside the scope of this code. Where this code includes provisions for maintaining means of egress and controlling occupant load, it is to facilitate the evacuation of items of cultural significance, allow access for damage limitation teams in an emergency, and prevent damage to collections through overcrowding or as an unintended consequence of an emergency evacuation.

• Library and museum collections that are privately owned and not open to the public shall not be required to meet the requirements of this code.

Since we are hard upon release of the 2021 Edition of NFPA 909 let us take a backward look at the current (2017) version of NFPA 909 Code for the Protection of Cultural Resource Properties – Museums, Libraries, and Places of Worship. Chapter 14 covers “Museums, Libraries and their Collections”. Chapter 15 covers “Places of Worship”

The 2025 Edition is now open for public input. Let us pick through proposals for the 2021 Edition to inform our approach to its improvement by referencing the technical committee transcripts linked below:

Public Input Report: January 12, 2023

N.B. We find committee response (accepted in principle) to Standards Michigan proposal to articulate conditions in which places of worship and libraries are used as community disaster relief support facilities. We consider this a modest “code win”.

Circling back to the ICC suite we find elevated interest in hardening community owned facilities to tornadoes, hurricane and floods and other storm related risk in the structural engineering chapters of the International Building Code.

Leadership and facility managers for enterprises of this type are encouraged to contribute obtain their own (free) NFPA public participation account in order to directly participate in the 2025 revision of NFPA 909 by logging in here: https://www.nfpa.org/login.

Public consultation on the First Draft of the 2025 Edition closes January 4, 2024.

This document is also a standing item on our periodic Prometheus, Lively and Fine Arts teleconference. See our CALENDAR for the next online meeting; open to everyone.![]()

Issue: [15-258]

Category: Fire Safety, Public Safety

Colleagues: Mike Anthony, Josh Elvove, Joe DeRosier

*See NFPA 101 Life Safety Code

LEARN MORE:

Guidelines for the Security of Rare Books, Manuscripts, and Other Special Collections, Association of College & Research Libraries, American Library Association, 50 East Huron Street, Chicago, IL 60611-2795.

“A Legal Primer on Managing Museum Collections,” Malaro, Marie, second edition 1998

“Risk and Insurance Management Manual for Libraries,” Mary Breighner and William Payton, edited by Jeanne Drewes, ALA 2005 ISBN 0-8389-8325-1.

Wisconsin Historic Building Code, Madison, WI:Wisconsin Administrative Code.

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670