Winter Holiday Fire Facts

NFPA Fire Protection Systems Catalog (Lorem ipsum)

Crosswalk: NFPA Fire Code and ICC International Fire Code

“Prometheus creating Man in the presence of Athena” 1802 Jean-Simon Berthélemy

Free public access to the current edition of NFPA’s parent fire safety document is linked below:

2024 NFPA 1 Fire Code

We attend to occupancy-specific chapters (listed below) because of their significant presence in education communities.

Chapter 25: Grandstands and Bleachers, Folding and Telescopic Seating, Tents and Membrane Structures (N.B)

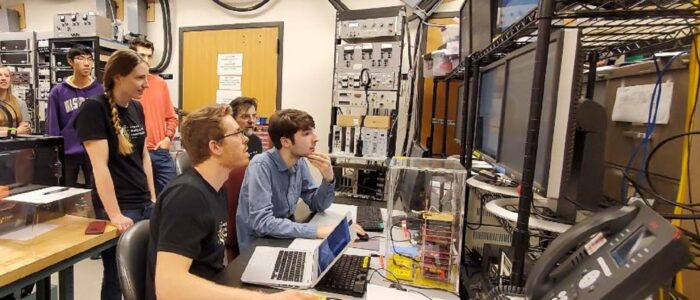

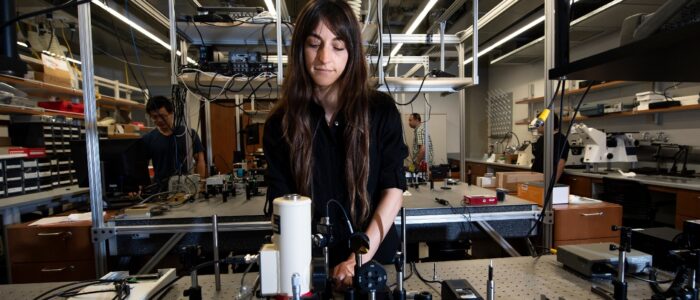

Chapter 26: Laboratories Using Chemicals

Chapter 29: Parking Garages

Chapter 32: Motion Picture and Television Production Studio Soundstages and Approved Production Facilities

Chapter 35: Animal Housing Facilities

Chapter 36: Telecommunication Facilities and Information Technology Equipment

Chapter 50: Commercial Cooking

Chapter 52: Energy Storage Systems

Some of the chapters reference other titles such as NFPA 45 Standard of Fire Protection for Laboratories Using Chemicals which support risk management in other occupancies. It is noteworthy that in the 2021 revision cycle of NFPA 1 there are relatively few new concepts regarding education facilities that have been proposed. You get a sampling of the ideas in play from the transcript of public input for the 2024 edition.

Public Input Report (525 Pages)

Use search terms such as school, college, university, dormitory(ies), laboratory(ies), classroom, children, day-care, student, et cetera for a sense of the ideas in play.

Results of the 2027 First Draft meetings have not yet been posted as on November 9, 2024. A preview of the ideas in play can be found in the meeting minutes of the several committees linked below:

Fire Code (FCC-AAC): First Draft Meeting Minutes

First Draft: Fundamentals of the Fire Code (FCC-FUN)

Special Equipment, Processes and Hazardous Materials (FCC-HAZ)

Building Systems and Special Occupancies (FCC-OCP)

Public comment on the First Draft of the 2027 revision will be received until April 24, 2025.

We include NFPA 1 on our periodic fire safety colloquia — identified by the mnemonic Prometheus — and march along peak interests.

Campus fire safety is domain relatively well-covered by other organizations such as the Center for Campus Fire Safety and HigherEd Safety so we place NFPA 1 in the middle of our priority tier. We are more interested in the harmonization of NFPA 1 with a competitor title International Fire Code; published by the International Code Council; to wit:

International Fire Code: The purpose of this code is to establish the minimum requirements consistent with nationally recognized good practice for proving a reasonable level of life safety and property protection from the hazards of fire, explosion or dangerous conditions in new and existing buildings, structures or premises and to provide a reasonable level of safety to fire fighters and emergency responders during emergency operations

Fire Code: The scope includes, but is not limited to, the following: (1) Inspection of permanent and temporary buildings, processes, equipment, systems, and other fire and related life safety situations (2) Investigation of fires, explosions, hazardous materials incidents, and other related emergency incidents (3) Review of construction plans, drawings, and specifications for life safety systems, fire protection systems, access, water supplies, processes, hazardous materials, and other fire and life safety issues (4) Fire and life safety education of fire brigades, employees, responsible parties, and the general public (5) Existing occupancies and conditions, the design and construction of new buildings, remodeling of existing buildings, and additions to existing buildings (6) Design, installation, alteration, modification, construction, maintenance, repairs, servicing, and testing of fire protection systems and equipment (7) Installation, use, storage, and handling of medical gas systems (8) Access requirements for fire department operations (9) Hazards from outside fires in vegetation, trash, building debris, and other materials (10) Regulation and control of special events including, but not limited to, assemblage of people, exhibits, trade shows, amusement parks, haunted houses, outdoor events, and other similar special temporary and permanent occupancies (11) Interior finish, decorations, furnishings, and other combustibles that contribute to fire spread, fire load, and smoke production (12) Storage, use, processing, handling, and on-site transportation of flammable and combustible gases, liquids, and solids (13) Storage, use, processing, handling, and on-site transportation of hazardous materials (14) Control of emergency operations and scenes (15) Conditions affecting fire fighter safety (16) Arrangement, design, construction, and alteration of new and existing means of egress

Note that both ICC and NFPA parent fire safety documents are developed on coincident 3-year cycles.

Issue: [18-90]

Category: Fire Safety, Public Safety

Colleagues: Mike Anthony, Joshua W. Elvove, Joe DeRosier, Casey Grant