Fire safety leadership usually finds itself involved in nearly every dimension of risk on the #WiseCampus; not just the built environment but security of interior spaces with combustibles but along the perimeter and within the footprint of the education community overall.

The Campus Fire Marshal, for example, usually signs the certificate of occupancy for a new building but may be drawn into meetings where decisions about cybersecurity are made. Fire protection systems coincide with evacuation systems when there is no risk and both may be at risk because of cyber-risk.

The job description of a campus fire safety official is linked below offers some insight into why fire safety technologies reach into every risk dimension:

University of California Santa Cruz Office of Emergency Services

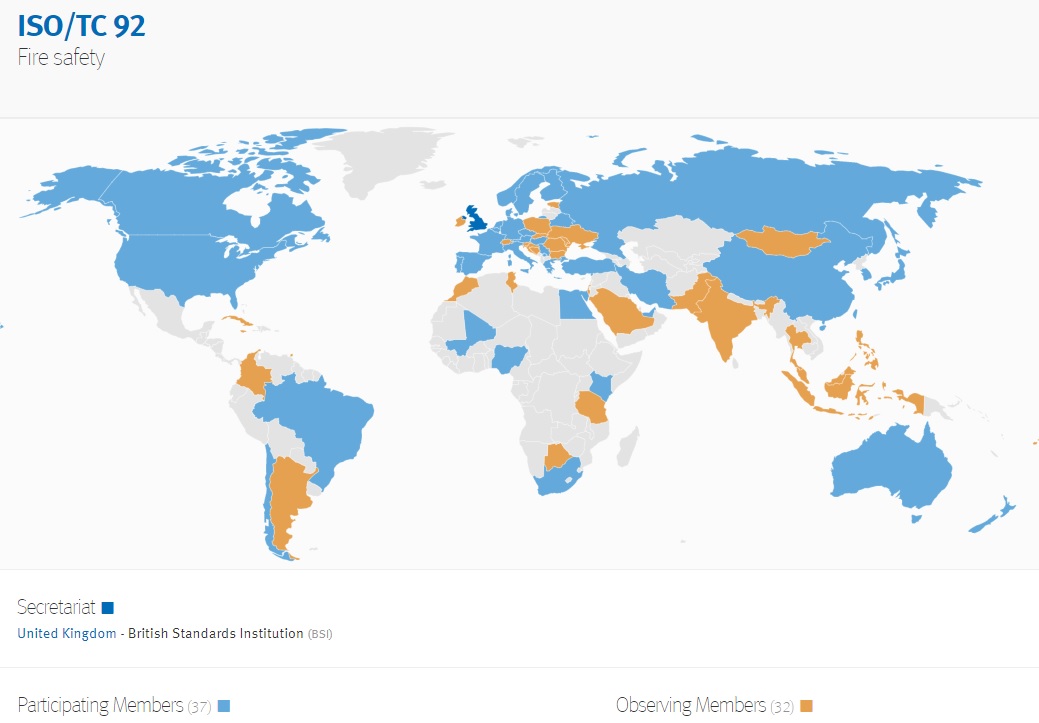

The development of the highest level fire safety consensus product in the world is led by the British Standards Institute, under the administration of the International Standardization Organization, with Committee E05 on Fire Standards of ASTM International as the US Technical Advisory Group Administrator. The business plan and the map of global participants is linked below:

BUSINESS PLAN ISO/TC 92 Fire safety EXECUTIVE SUMMARY

The consensus products developed by TC 92 are intended to save lives, reduce fire losses, reduce technical barriers to trade, provide for international harmonization of tests and methods and bring substantial cost savings in design. ISO/TC 92 standards are expected to be of special value to developing countries, which are less likely to have national standards. As with all ISO standards, the TC 92 consensus product is a performance standard suitable for use in prescriptive regulations and provide for a proven route to increased fire safety.

We do not advocate in this standard at the moment; we only track it. The International Fire Code and the Fire Code have been our priorities since 2006. The fire safety space is well populated with knowledgeable facility professionals because conformity budgets in the fire safety world — i.e. the local or state fire marshal — usually has a budget. When you have a budget you usually have people keeping pace with best practice.

We encourage our colleagues in the United States on either the business or academic side of the education facility industry to communicate directly with ANSI’s ISO Team and/or the ASTM Contact: Tom O’Toole, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959 Phone: (610) 832-9739, Email: totoole@astm.org

We maintain this title on the agenda of our periodic Global and Prometheus colloquia. See our CALENDAR for the next online meeting; open to everyone.

Issue: [19-104]

Category: Fire Safety, Fire Protection, International

Contact: Mike Anthony, Joe DeRosier, Alan Sactor, Joshua Elvove, Casey Grant

More:

The Challenges of Storage and Not Enough Space, Alan Sactor