Beef Stew and Buttermilk Biscuits

- Home Page 67

Perfect your omelette

A commercial kitchen is a kind of laboratory

When the student surpasses the teacherpic.twitter.com/ZfyxpL2YzS

— Wolf of X (@tradingMaxiSL) January 7, 2026

Fried chicken with sweet sauce and cabbage, mid sized portion of rice, okra with mustard and shredded chicken, sweet egg omelette with waffles and cream at Ritsumeikan University in Kyoto, Japan 🇯🇵

💶 752yen (~5,25€) pic.twitter.com/4jKnpNrQEy

— Mensa Scran (@MensaScran) October 30, 2022

Eccles Cakes

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Power Distribution Units

Today we veer (slightly) from our primary interest in interoperability standards to explore the moment in best practice discovery and promulgation in the hardware supporting the artificial intelligence zietgeist. Use the login credentials at the upper right of our home page.

Carnegie-Mellon: Planning & Design Considerations for Data Centers

University of Kansas Data Center and Server Room Standards

Power Distribution Units (PDUs) are critical in data centers, serving as the backbone for reliable power management. They distribute electricity from the main power source to servers, networking equipment, and other devices, ensuring consistent and stable power delivery.

PDUs offer features like load balancing, surge protection, and remote monitoring, which optimize energy efficiency and prevent outages. By providing multiple outlets and circuit protection, they safeguard expensive equipment from power fluctuations. Advanced PDUs enable real-time data tracking, aiding in capacity planning and fault detection.

Ultimately, PDUs ensure uptime, operational efficiency, and scalability in data centers. We track, and sometimes participate, in the standards setting for these organizations develop the key standards that govern PDU design, safety, efficiency, and interoperability, influencing global manufacturing compliance:

UL (Underwriters Laboratories): Establishes safety standards like UL 60950-1 for IT equipment, ensuring PDUs prevent hazards in high-density environments.

IEC (International Electrotechnical Commission): Develops core electrical standards such as IEC 60950-1 and IEC 62368-1 for low-voltage safety and audio/video/IT equipment, critical for PDU power handling.

ENERGY STAR (U.S. EPA): Sets efficiency benchmarks for PDUs, promoting low-loss designs to minimize data center energy waste (up to 12% savings).Related:

Power Management For Data Centers Challenges And Opportunities

TIA 92

Uptime Institute

Related:

2029 National Electrical Code

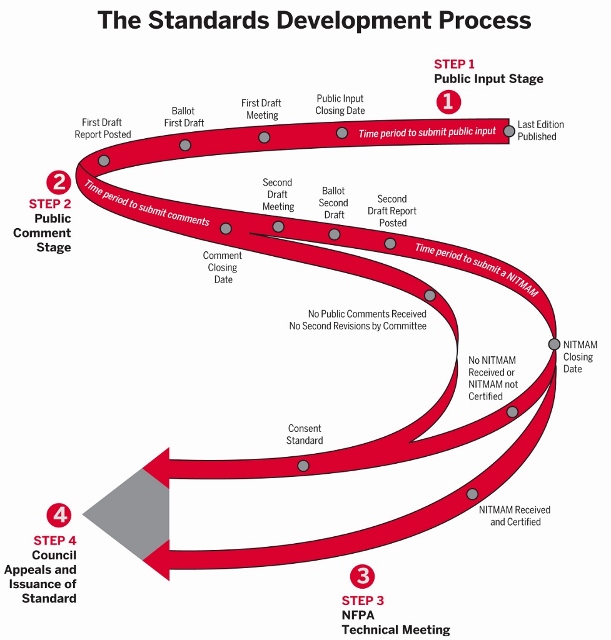

Public input on the 2029 Revision will be received until April 9th. Over the next weeks and months — typically meeting twice a day every Tuesday — we will pull forward our previous proposals and draft original proposals relevant to the education and healthcare electrotechnical infrastructure of educational settlements. Link to Proposed Reorganization.

Photo at 2723 State Street Office*

Mike was part of the National Electrical Code Quarter Century Club but was at another conference and not able to receive the award at the June conference. University of Michigan support began in 1993. IEEE support began in 2014.

*New Office (a short walk across the street) starting October 1: 455 East Eisenhower, Ann Arbor, MI 48108

Current Issues and Recent Research

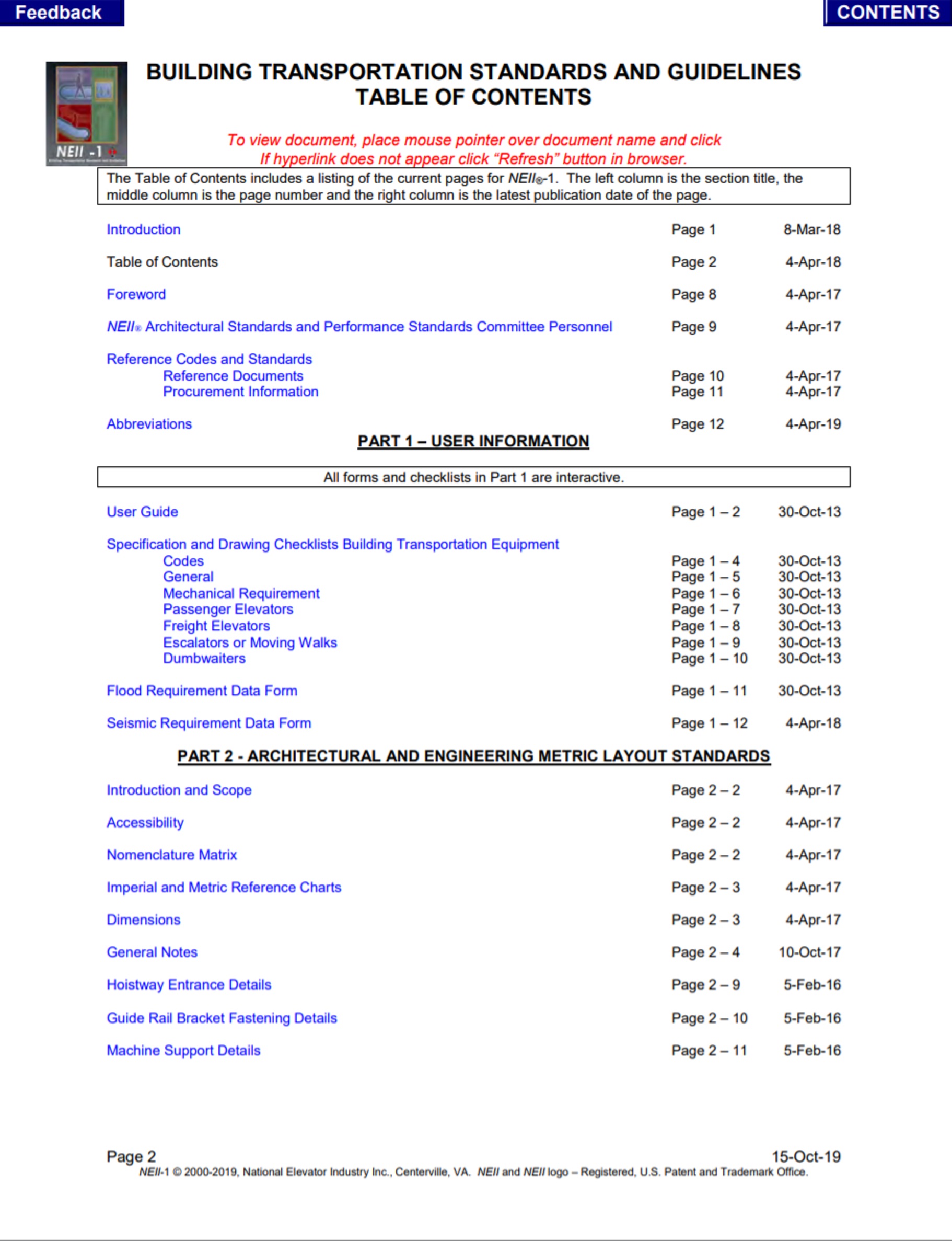

Today we examine Second Draft transcripts of the Special Equipment Chapter 6 (CMP-12) and product inspection, testing and certification listings that appear Annex A (CMP-1).

Once every eighteen months we spend a week drilling into the National Electrical Code by submitting new proposals or comments on proposed revisions. Today we review the actions taken by the technical committees on the First Draft. Responses to committee actions will be received until August 26th.

Interconnected Electric Power Production Sources “Microgrids”

Fire Protection Research Institute | Evaluation of Electrical Feeder and Branch Circuit Loading

Originally posted October 16, 2016

University of Michigan Law School![]()

With thanks to Richard Robben, President of True North Facility Management, the pledges to fund the NFPA Fire Protection Foundation Project: Evaluation of Electrical Feeder and Branch Circuit Loading accumulated to the requisite $24,000 to begin Phase I of two phases of a project originally begun by the University of Michigan to bring the National Electrical Code (NFPA 70) in line with federal energy conservation regulations that incorporate by reference the International Energy Conservation Code.

NFPA 70 is one of the most widely used standards for electrotechnology in the world. The University of Michigan began assertive advocacy on behalf of the US education industry in the NFPA suite in 1996 and that advocacy has expanded globally under two different private organizations: See About

Phase I is now completed. The Phase I Final Report (with public comments) is available in the links below:

REPORT – Branch Circuit Loading Phase1 FINAL

SUMM – Panel Comments – Branch Circuit Loading FINAL2

In October, the project Principal Researcher, Tammy Gammon, provided an update to the NFPA Research Foundation. Her slides are available in the link below:

We wish to thank our colleagues at Notre Dame who helped “get the ball rolling”, our colleagues in the Big Ten & Friends consortia, and forward-thinking manufacturers for their pledges:

Eaton Corporation

MIAPPA | Michigan Association of Physical Plant Administrators

Michigan State University

Ohio State University

University of Iowa

University of Minnesota

University of Nebraska

University of Texas Austin

Issue [13-33]

Contact: Mike Anthony, Jim Harvey, Richard Robben (True North, LLC); Tom Harman (University of Houston Clearwater), Kane Howard (Michigan State University), Paul Kempf (Notre Dame)

Colleagues: Robert G. Arno (Harris Corp), Joe Weber (Emerson), Casey Grant (NFPA), Larry Ayers (Independent Electrical Contractors Association)

Category: Electrical, Energy Conservation

Intellectual Property

It is impossible to overestimate the sensitivity of this topic but poke at it, we will. At the moment, the less written here; the better. Much of this domain is outside our wheelhouse; though it has settled on a few first principles regarding patents, trademarks and copyrights relevant to the user-interest we describe in our ABOUT.

Many large research universities have a watchdog guarding its intellectual property and trying to generate income from it, and; of course, for branding. We will dwell on salient characteristics of the intellectual property domain with which we reckon daily — highlighting the market actors and the standards they have agreed upon.

Additionally, technical standards developers are generally protected by copyright law, as the standards they create are typically considered original works of authorship that are subject to copyright protection. In the United States, the Copyright Act of 1976 provides copyright protection for original works of authorship, which includes technical standards. This means that the developers of technical standards have the exclusive right to reproduce, distribute, and create derivative works based on their standards, and others must obtain permission or a license to use or reproduce the standards.

Some technical standards may be subject to certain exemptions or limitations under copyright law. In the United States, there is a doctrine called “fair use” that allows for limited use of copyrighted works for purposes such as criticism, comment, news reporting, teaching, scholarship, or research, without the need for permission or a license from the copyright owner. Almost everything we do at Standards Michigan falls under the fair use doctrine. This is why we have no search feature and most pages are protected. If we err in this; let us know.

More

- Patent Act: This is the primary federal law governing patents in the United States. It sets forth the requirements for obtaining a patent, the rights of patent owners, and the remedies available for infringement.

- The Sherman Antitrust Act of 1890 and the Clayton Antitrust Act of 1914 prohibit anticompetitive behavior in the marketplace, including the use of codes and standards to exclude competition.

- Title 37 of the Code of Federal Regulations: This contains the rules and procedures related to patents, including rules governing the filing and examination of patent applications.

- America Invents Act: This is a major overhaul of the U.S. patent system that was enacted in 2011. It includes provisions such as the transition to a “first-inventor-to-file” system and the creation of new post-grant review procedures for challenging the validity of patents.

- Manual of Patent Examining Procedure: This is a guidebook for patent examiners that provides detailed information on the rules and procedures for examining patent applications.

- Everett Rogers: Diffusion of innovations

- Copyright Law of the United States (Title 17)

ASTM International Intellectual Property Policy

Healthcare Standards Institute IP Policy

International Code Council Copyright Protection

Underwriters Laboratory Patent Policy

Vad är en standard? Syftet med standarder är att skapa enhetliga och transparenta rutiner som vi kan enas kring. Det ligger ju i allas intresse att höja kvaliteten, undvika missförstånd och slippa uppfinna hjulet på nytt varje gång. https://t.co/zKhgPXPdpW pic.twitter.com/oKejdKSm47

— Svenska institutet för standarder, SIS (@svenskstandard) July 15, 2019

Innovation – Market Acceptance – Standardization – Human Right

Evensong “Sleep”

Composed in 2000 Eric Whitacre’s “Sleep” sets the poetry of Robert Frost to music. Widely acclaimed for its subtlety in dissonance and consonance. A classic in the contemporary choral repertoire.

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670