Adam Lock: Associate Chair for Farm Operations, Michigan State University

“Buttergate”

- Home Page 134

Nuper editum

Last mystery reader… Mrs. Weber! We really love the dinosaur book! pic.twitter.com/0JUtouJVfL

— Jessica Hickey (@HickeyKdg) February 28, 2025

Our Year 4 boys have enjoyed making Victorian Portraits this morning as part of our Victorian topic! #HazlegroveYear4 #HazlegrovePrep #HazlegroveHistory pic.twitter.com/AjLrFKpl0z

— Academic Studies | Hazlegrove Prep (@HZG_Academic) March 1, 2025

Gwinnett Environmental & Heritage Center @MVESGainesville pic.twitter.com/7U4wo7X8YB

— Dawn Bishop (@dawn_bishop) February 28, 2025

K-2 Garden Club is off to a beautiful start! We can’t wait to have more fun in the dirt this spring!🌷🌿 ☀️@MVESGainesville @Hall_Schools @h2o3rdgrade @MrsRiley_MVES pic.twitter.com/6JQG2M2jHR

— Rebecca Bowman (@MrsBowman2MVES) February 28, 2025

5th Grade Field Trip to 30 Bowl in Fremont! Mr. Thayer taught the students how to bowl in PE class, and now they get to bowl at a real bowling alley! @YutanChieftains pic.twitter.com/okoEcKmhoO

— Katie Thompson (@mrsthompson05) February 28, 2025

The weekend is calling, but first… take a moment to read, organize, plan, smile and celebrate. pic.twitter.com/KP7u4ZzWVd

— 🍎Teacher Tee of the Library📚📖📒📝 (@TeacherTeeK_3) February 28, 2025

Audio/video, information & communication technology

Performance in the Bolshoi Theatre Theateraufführung im Moskauer Bolschoi-Theater (Chromolithographie)

Even before the pandemic, massive open online curriculum, continued growth of consumer demand for “content” and the expansion of college and universities cultural and entertainment activity, drove our interest in the technologies that make it possible to produce and deliver “content” from facilities that are safe and sustainable.

As covered in our other Lively colloquia there are about 20 accredited standards developers that claim some part of this domain, or expanding their charter to meet the demand for best practice titles. To repeat: “Standards are the seed corn for compliance revenue. They fertilize the land for litigation.” These generally well-meaning organizations only invest in the administration of best practice discovery and promulgation if they see demand for conformance revenue in their future.

Education communities in every nation are also conformance organizations.

Cultural content discovery, creation and delivery depends heavily on electrotechnology.

The parent committee of the highest level of electrotechnology standardization in this domain world is International Electrotechnical Commission Technical Committee TC 108: Safety of electronic equipment within the field of audio/video, information technology and communication technology. Safety first. A committee with a similar sounding title, but a different scope is IEC TC 100 Audio, video and multimedia systems and equipment — the subject of a separate post*.

To paraphrase the IEC TC 108 Committee Scope Statement:

Horizontal safety function: Methods of measuring touch current and protective conductor current. This includes, for various types of equipment, methods of measurement of touch current with regard to physiological effects and of protective conductor current for installation purposes. The methods of measurement consider both normal conditions and certain fault conditions. Safety of equipment electrically connected to a telecommunication network

Group safety function:Audio, video and similar electronic apparatus – Safety requirements Audio/video, information and communication technology equipment and safety of remote power feeding.

According to its Strategic Business Plan, the need for standardization in this technology shows up in unexpected places such as 3-dimensional printing and wearable smart devices; both of which are of interest to faculty, students and the staff that supports the physical infrastructure.

The home page for the IEC public commenting facility is linked below:

We generally refer action in global electrotechnology standards to any one of several IEEE Societies and collaborate with the IEEE Education & Healthcare Facilities Committee (IEEE E&H). We also track and participate in the standards action of several trade associations that service some part of this space; all of whom are sensitive to the international electrotechnology standards action. Colleges and universities with federally funded facilities may need to be attentive to Trade Agreement Act matters when acquiring equipment of this nature.

As of this posting there are no Committee Draft Vote (CDV) documents released by TC 108 seeking public comment but we include it in our periodic scan of best practice literature. We generally refer to the tracking facility available with the IEEE E&H hosted on a University of Michigan server for educational purposes. IEEE E&H meets 4 times monthly European and American time zones.

We always encourage subject matter experts with front line experience planning, designing building, operating and maintaining these growing and complicated spaces. We recommend US-based experts contact Tony Zertuche, Director, International Policy and General Secretary, USNC/IEC (tzertuche@ansi.org).

United States National Committee of the International Electrotechnical Commission (USNC/IEC)

We renew our understanding of electrotechnology standards for Lively Arts at least once a month. See our CALENDAR. The IEEE Education & Healthcare Facilities Committee meets online every other Tuesday in both Central European time American time zones. Its meeting dates and login credentials are available on its home page.

Issue: [Various]

Category: Electrical, Infotech, Global, Lively Arts

Colleagues: Mike Anthony, Jim Harvey, Giuseppe Parise

* Related work runs through ISO Technical Committee 36 .

Snow Load

SNOW LOADS: GUIDE TO THE SNOW LOAD PROVISIONS OF ASCE 7-10

Library of Congress 2010 Edition

A tool for removing the snow from a roofpic.twitter.com/bYyVMrJZKD

— Massimo (@Rainmaker1973) January 27, 2025

Solar Panels on Roofs Only

This content is accessible to paid subscribers. To view it please enter your password below or send mike@standardsmichigan.com a request for subscription details.

Security 200

09-1185 – Pena et al v. Cid | Casetext PENA v. CID

“We worry about what a child will become tomorrow,

yet we forget that he is someone today.”

– Stacia Tauscher

Today we run a status check on the stream of technical and management standards evolving to assure the highest possible level of security in education communities. The literature expands significantly from an assortment of national standards-setting bodies, trade associations, ad hoc consortia and open source standards developers. CLICK HERE for a sample of our work in this domain.

School security is big business in the United States. According to a report by Markets and Markets, the global school and campus security market size was valued at USD 14.0 billion in 2019 and is projected to reach USD 21.7 billion by 2025, at a combined annual growth rate of 7.2% during the forecast period.

Another report by Research And Markets estimates that the US school security market will grow at a compound annual growth rate of around 8% between 2020 and 2025, driven by factors such as increasing incidents of school violence, rising demand for access control and surveillance systems, and increasing government funding for school safety initiatives.

Because the pace of the combined annual growth rate of the school and campus security market is greater than the growth rate of the education “industry” itself, we’ve necessarily had to break down our approach to this topic into modules:

Security 100. A survey of all the technical and management codes and standards for all educational settings — day care, K-12, higher education and university affiliated healthcare occupancies.

Security 200. Queries into the most recent public consultations on the components and interoperability* of supporting technologies

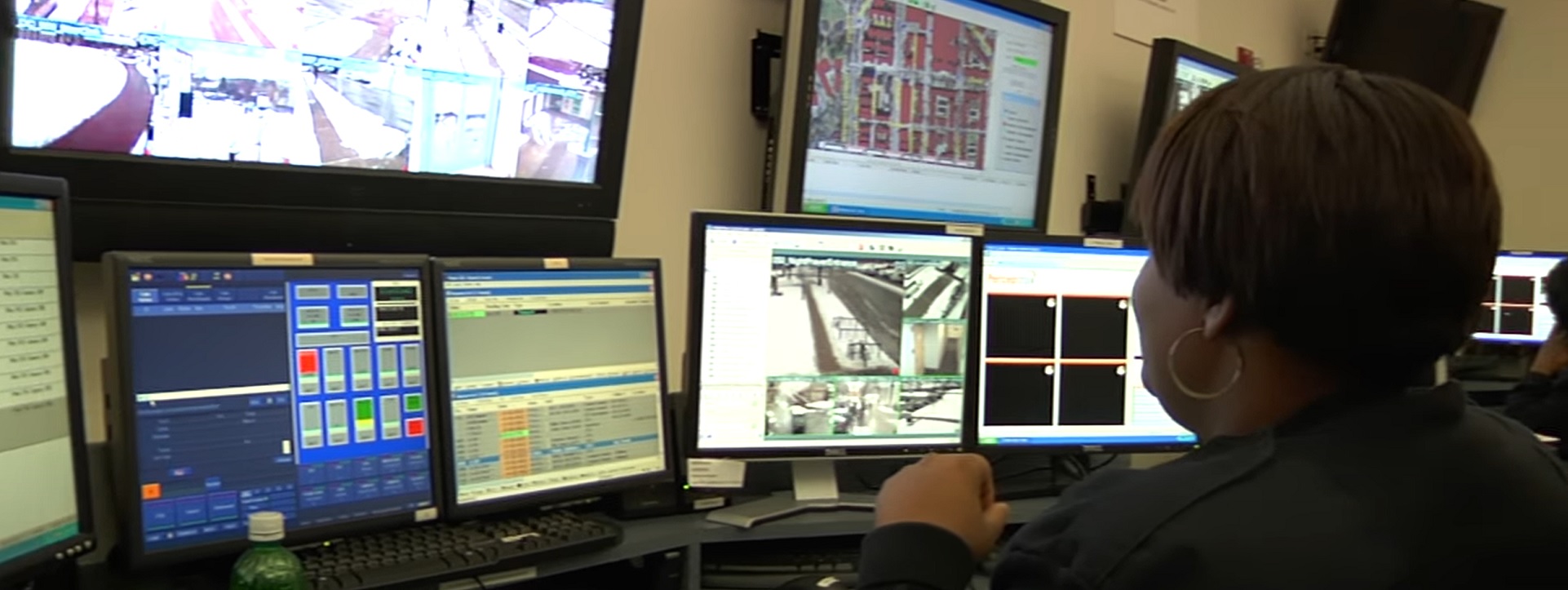

Video surveillance: indoor and outdoor cameras, cameras with night vision and motion detection capabilities and cameras that can be integrated with other security systems for enhanced monitoring and control.

Access control: doors, remote locking, privacy and considerations for persons with disabilities.

Panic alarms: These devices allow staff and students to quickly and discreetly alert authorities in case of an emergency.

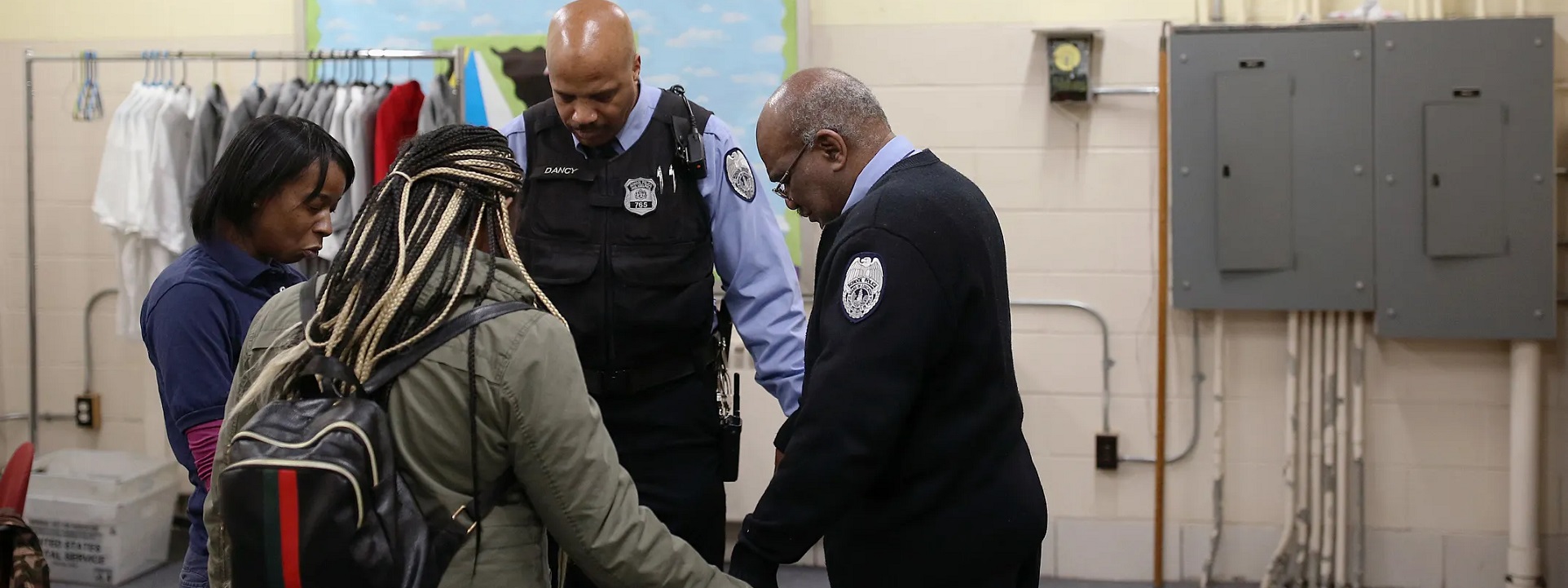

Metal detectors: These devices scan for weapons and other prohibited items as people enter the school.

Mass notification systems: These systems allow school administrators to quickly send emergency alerts and notifications to students, staff, and parents.

Intrusion detection systems: These systems use sensors to detect unauthorized entry and trigger an alarm.

GPS tracking systems: These systems allow school officials to monitor the location of school buses and track the movements of students during field trips and other off-campus activities.

Security 300. Regulatory and management codes and standards; a great deal of which are self-referencing.

Security 400. Advanced Topics.

As always, we reckon first cost and long-term maintenance cost, including software maintenance for the information and communication technologies (i.e. anything with wires) installed in the United States. Cybersecurity is outside our wheelhouse and beyond our expertise. In order to do any of the foregoing reasonably well, we have to leave cybersecurity standards to others.

When your students love the school security guard- he gets flowers! Thanks, Steve! You are the BEST and we appreciate your hard work keeping us safe and building relationships! pic.twitter.com/VCJQ6y9S44

— Casey Otten (@casey_otten) May 26, 2023

Education Community Safety catalog is one of the fast-growing catalogs of best practice literature. In developing district security plans, K-12 school leaders stress that school safety is a cross-functional responsibility and every individual’s participation drives the success of overall safety protocols. We link a small sample below and update ahead of every Security colloquium.

Artificial Intelligence Tries (and Fails) to Detect Weapons in School

Could AI be the future of preventing school shootings?

Executive Order 13929 of June 16, 2020 Safe Policing for Safe Communities

National Center for Education Statistics: School Safety and Security Measures

International Code Council

2021 International Building Code

Section 1010.1.9.4 Locks and latches

Section 1010.2.13 Delayed egress.

Section 1010.2.14 Controlled egress doors in Groups I-1 and I-2.

Free Access: NFPA 72 National Fire Alarm and Signaling Code

Free Access: NFPA 731 Standard for the Installation of Premises Security Systems

IEEE: Design and Implementation of Campus Security System Based on Internet of Things

APCO/NENA 2.105 Emergency Incident Data Document

C-TECC Tactical Emergency Casualty Care Guidelines

Department of Transportation Emergency Response Guidebook 2016

NENA-STA-004.1-2014 Next Generation United States Civic Location Data Exchange Format

Example Emergency Management and Disaster Preparedness Plan (Tougaloo College, Jackson, Mississippi)

Partner Alliance for Safer Schools

Federal Bureau of Investigation Academia Program

Most Dangerous Universities in America

Federal Bureau of Investigation: Uniform Crime Reporting Program

* Interoperability refers to the ability of different technologies or systems to communicate and work together seamlessly. In the context of school security technologies, interoperability can help improve the effectiveness of security systems and make it easier for school personnel to manage and respond to potential security threats. Here’s what we look for:

- Standardization: By standardizing communication protocols and data formats, school security technologies can be made more compatible with each other, making it easier for different systems to communicate and share information.

- Integration: School security technologies can be integrated with each other to provide a more comprehensive security solution. For example, access control systems can be integrated with video surveillance systems to automatically trigger alerts when an unauthorized person enters a restricted area.

- Open Architecture: Open architecture solutions enable different security systems to be connected and communicate with each other regardless of their manufacturer or supplier. This approach makes it easier to integrate different technologies and avoid vendor lock-in.

- Cloud-based Solutions: Cloud-based security solutions can enable interoperability by providing a centralized platform for managing and monitoring different security systems. This approach can also simplify the deployment of security technologies across multiple locations.

- Collaboration: School security technology providers can work together to develop interoperability standards and best practices that can be adopted across the industry. Collaboration can help drive innovation and improve the effectiveness of security systems.

Clery Act

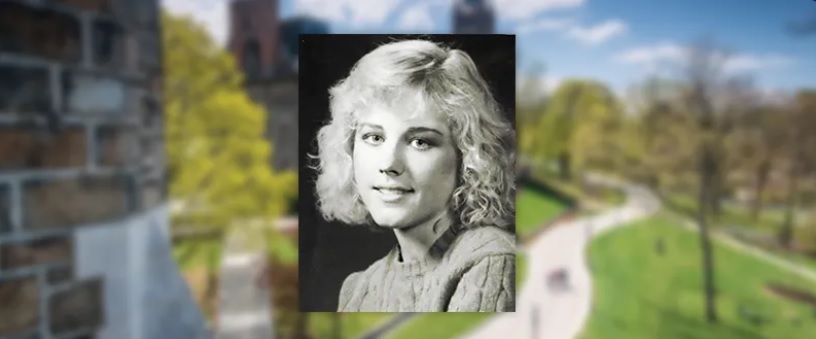

Update: February 26, 2025

The federal requirement for a school safety plan is outlined in the Jeanne Clery Disclosure of Campus Security Policy and Campus Crime Statistics Act, commonly known as the Clery Act. The Clery Act requires all colleges and universities that participate in federal student financial aid programs to develop and publish an annual security report that includes certain safety-related policies, procedures, and crime statistics.

The Clery Act requires that schools include specific information in their security reports, including:

- The school’s crime statistics for the previous three years.

- Information about the school’s policies and procedures related to campus safety and security.

- Information about crime prevention programs and services offered by the school.

- Information about the school’s emergency response and evacuation procedures.

- Information about the school’s policies and procedures for addressing and reporting incidents of sexual assault, domestic violence, dating violence, and stalking.

- Information about the school’s drug and alcohol policies and prevention programs.

While the Clery Act only applies to colleges and universities that receive federal student financial aid, many states and school districts have adopted similar requirements for K-12 schools to develop and implement comprehensive safety plans. These plans may include many of the same elements as Clery Act-compliant security reports, such as emergency response protocols, crime prevention programs, and policies for addressing incidents of violence and harassment.

Example Reports:

University of Michigan Ann Arbor Annual Security and Fire Safety Report 2024

Michigan State University: 2022 Annual Security & Fire Safety Report

Davenport University: 2022 Annual Security and Fire Safety Report

Central Michigan University: 2022 Annual Security & Fire Safety Report

Related:

Record-Breaking $14 Million Fine Imposed for Noncompliance with the Clery Act

March 2020 Update

The most recent changes to the Clery Act were made in March 2020, when the Department of Education published the final rule amending the Clery Act regulations. The changes include:

- Expanding the definition of sexual harassment to include quid pro quo and hostile environment harassment, which aligns with Title IX regulations.

- Requiring institutions to report stalking and domestic violence in addition to existing crime categories.

- Adding hazing as a reportable crime category.

- Requiring institutions to compile and publish hate crime statistics for all categories of prejudice, including gender identity and national origin.

- Requiring institutions to include specific policies and procedures in their annual security reports, such as those related to prevention and response to sexual assault, domestic violence, dating violence, and stalking.

- Requiring institutions to provide survivor-centered and trauma-informed services to individuals who report or experience sexual assault, domestic violence, dating violence, or stalking.

- Requiring institutions to include information about prevention and response to cyberbullying and electronic harassment in their annual security reports.

- Allowing institutions to provide annual security reports electronically and requiring institutions to make their crime statistics publicly available on their website.

These changes aim to strengthen the Clery Act’s requirements for campus safety and to better address sexual harassment and other forms of violence on college and university campuses.

Clery Act Appendix for FSA Handbook

| Every new federal law involving paperwork creates an uncountable number of trade associations and compliance enterprises. A simple web search on “Cleary Act” will reveal half the internet full of pages for more information. Our focus is on the user-side — i.e. making inquiries and pushing back on the gaudy proliferation of regulatory requirements, the integrity of purpose of the law notwithstanding. We maintain this title on the standing agenda on all of our Security colloquia. See our CALENDAR for the next online meeting; open to everyone. |

Catalog: BUILDERS HARDWARE MANUFACTURER ASSOCIATION

Builders Hardware Manufacturer Association Standards Catalog

ARCHIVE: April 6, 2019

The Builders Hardware Manufacturers Association (BHMA) is an ANSI accredited standards developing organization for building access and egress technology that education industry real asset managers find referenced deep in the architectural and electrical sections of construction contract specifications (as in “Conform to all applicable standards”). Architects, electrical, fire protection and information and communications technology professionals usually have to collaborate on the design, construction. operations and maintenance of fenestration technologies.

Gone are the days when a door was just a door (or “opening” or “fenestration”). Doors are now portals; an easily identifiable control point in the Internet of Things electrotechnical transformation. There are 100’s of thousands of them on large research university campus; for example. As we explain in our School Security Standards post the pace of standardization in public safety management and technology has increased; driven by events. Some of the risk management can be accomplished with integrated technical solutions that are complex and more expensive to design, build, operate and maintain.

A fair estimate of the annualized cost of a door now runs on the order of $1000 to $10,000 per door (with hospital doors at the high end).

BHMA develops and maintains performance standards for locks, closers, exit devices and other builders hardware. It has more than 40 ANSI/BHMA standards. The widely known ANSI/BHMA A156 series of standards describes and establishes features and criteria for an array of builders hardware products including locks, closers, exit devices, butts, hinges, power-operated doors and access control products. They are listed on the link below:

BHMA has opened one of its standards for public review that is relevant to our contribution to the security and sustainability agenda of the education facility industry; an agenda that necessarily involves a growing constellation of interacting specifics

BHMA A156.4 Standard for Door Controls – Closers. This Standard contains requirements for door closers surface mounted, concealed in the door, overhead concealed, and concealed in the floor. Also included are pivots for floor closers. Criteria for conformance include cycle, operational, closing force, and finish tests.

Given that BHMA consensus products are largely product standards (much the same way UL Standards are product standards) it is wise to keep an eye on a related installation standards found in the fenestration sections of model building and fire safety codes and in ASTM E2112 Standard Practice for Installation of Exterior Windows, Doors and Skylights.

Comments are due May 6th. You may obtain an electronic copies of any of the foregoing from MTierney@kellencompany.com and send comments to the same (with copy to psa@ansi.org).

The BHMA suite is on the standing agenda of our monthly Construction Specification and Design Guideline teleconference; an informal session that should interest building contractors and design professionals who prepare documents that use the general purpose clause: “Conform to all applicable standards”. That usually means the latest standard. See our CALENDAR for the next online meeting; open to everyone.

Issue: [19-129]

Category: Architectural, Electrical, Facility Asset Management, Telecommunication, Public Safety, #SmartCampus, Risk Management

Colleagues: Mike Anthony, Jim Harvey. Jim Vibbart

LEARN MORE:

BHMA Standards Revision Status Tracking

Guide to Premises Security

2026 Revision First Draft Ballot | NFPA 730

2026 Revision First Draft Report | NFPA 731

First Draft Meeting Agenda (Meetings were remote)

NFPA 731: Standard for the Installation of Premises Security Systems

NFPA 730 Guide to Premise Security guide describes construction, protection, occupancy features, and practices intended to reduce security vulnerabilities to life and property. Related document — NFPA 731 Standard for the Installation of Electronic Premises Security Systems covers the application, location, installation, performance, testing, and maintenance of electronic premises security systems and their components.

The original University of Michigan standards advocacy enterprise (see ABOUT) began following the evolution of NFPA 730 and NFPA 731 since the 2008 Edition. That enterprise began a collaboration with trade associations and subject matter experts from other universities (notably Georgetown University and Evergreen State University) to advocate user-interest concepts in the 2011 edition. A summary of advocacy action is summarized in the links below:

in the appeared in a trade association journal Facilities Manager:

APPA Code Talkers Anthony Davis Facility Manager May June 2011

An online presentation by Michael C. Peele (Georgetown University) — one of the voting members of NFPA 730 and NFPA 731 technical committees– was recorded and is linked below.

FREE ACCESS: 2023 Guide for Premises Security

FREE ACCESS: 2018 NFPA 730 Guide to Premise Security

Public comment on the First Draft of the 2026 Edition will be received until January 3, 2025. You may key in your own ideas by clicking in to our user-interest Public Consultation Meeting Point or by communicating directly with the NFPA.

This title remains on the standing agenda of our Security colloquia. See our CALENDAR for the next online meeting; open to everyone.

New update alert! The 2022 update to the Trademark Assignment Dataset is now available online. Find 1.29 million trademark assignments, involving 2.28 million unique trademark properties issued by the USPTO between March 1952 and January 2023: https://t.co/njrDAbSpwB pic.twitter.com/GkAXrHoQ9T

— USPTO (@uspto) July 13, 2023

Standards Michigan Group, LLC

2723 South State Street | Suite 150

Ann Arbor, MI 48104 USA

888-746-3670